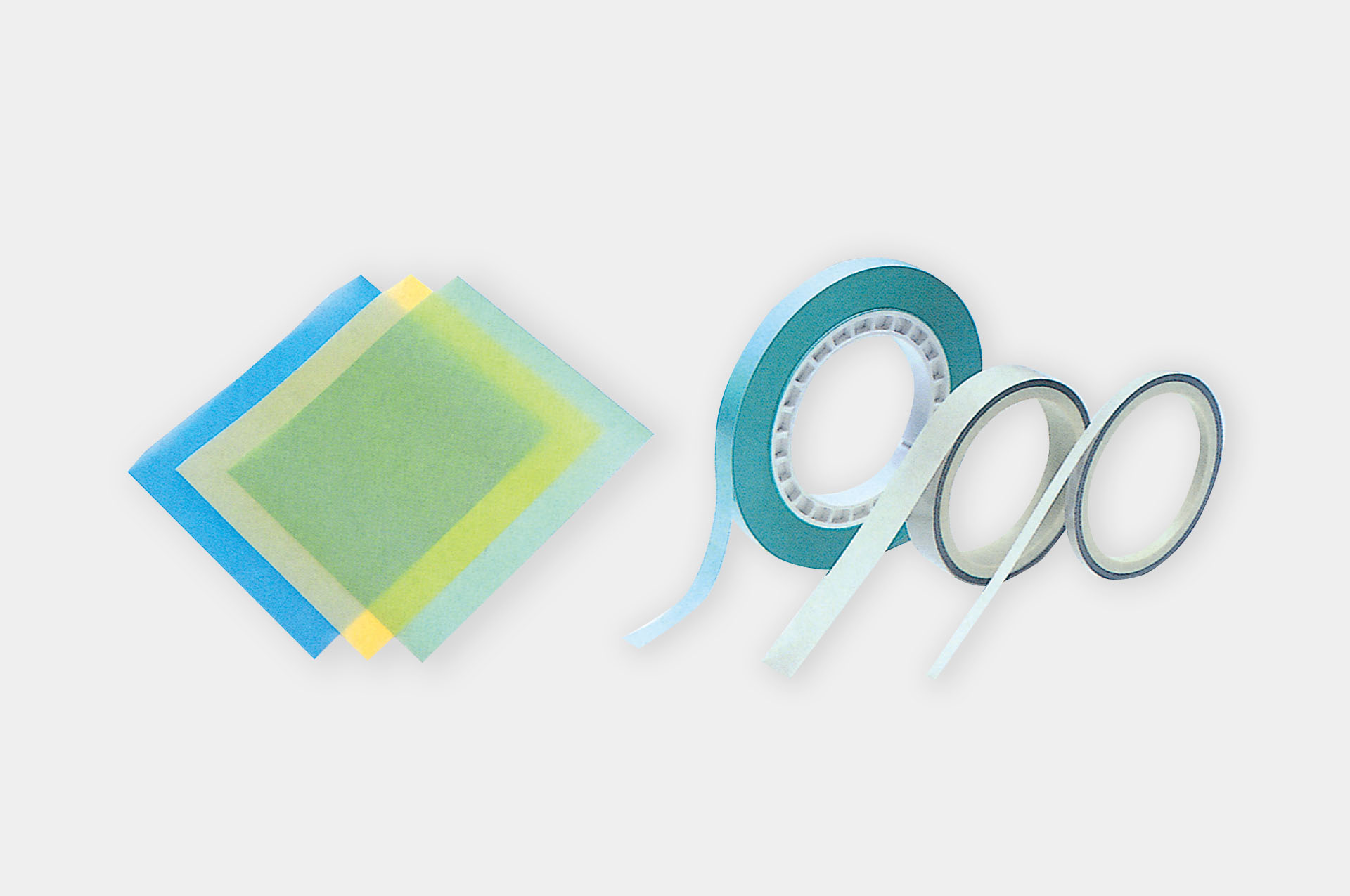

Lapping film

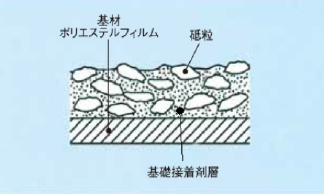

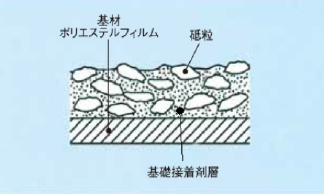

Lapping film has uniformly despersed ultra-fine abrasive grains in a resin.

That provides a uniformly finished surface without deep scratches.

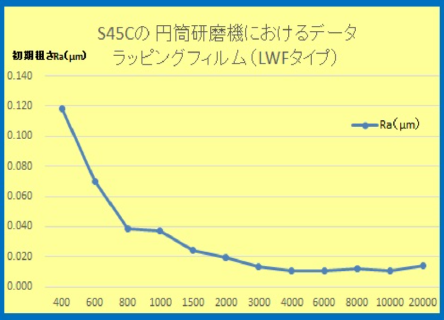

Film abrasives are flexible and have fixed abrasive grains for a good working environment. It can be used in both dry and wet processes, and accuracy can be easily achieved by selecting the right film.

LWF and LDF are color-coded by count.

Abrasive grain type: WA (white Alminum oxide)

GC (Green Carborundum)

CC (Carborundum)

D (Diamond)

Base material: 25Μ = 1 mil 75Μ = 3 mil

That provides a uniformly finished surface without deep scratches.

Film abrasives are flexible and have fixed abrasive grains for a good working environment. It can be used in both dry and wet processes, and accuracy can be easily achieved by selecting the right film.

LWF and LDF are color-coded by count.

Abrasive grain type: WA (white Alminum oxide)

GC (Green Carborundum)

CC (Carborundum)

D (Diamond)

Base material: 25Μ = 1 mil 75Μ = 3 mil

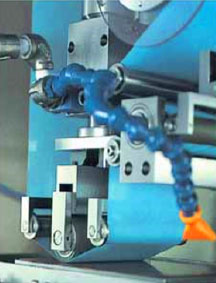

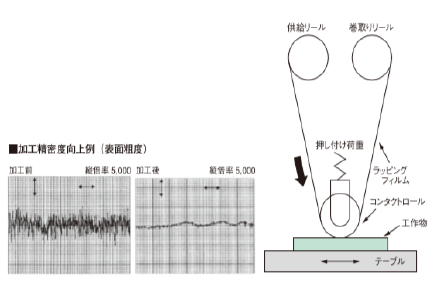

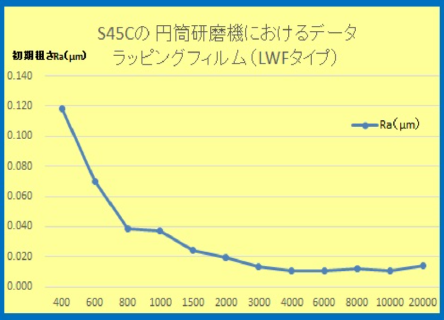

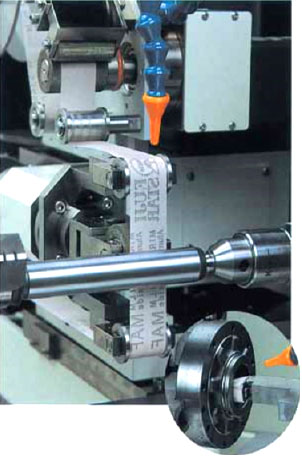

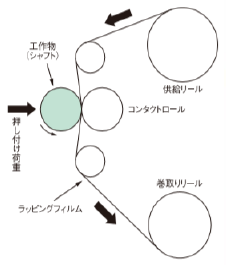

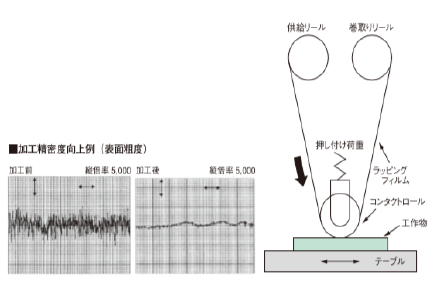

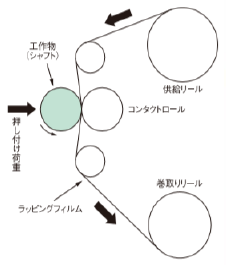

Example of super-finishing process with continuous supply of film abrasive

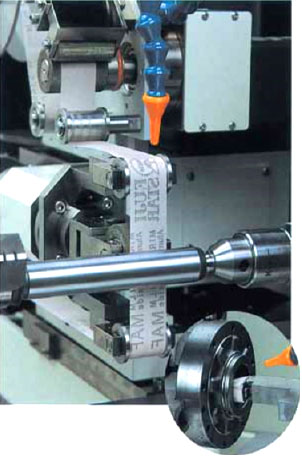

Super-finishing and polishing of inner and outer diameter of shafts

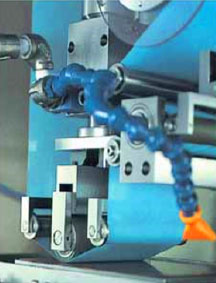

The film abrasive, which takes advantage of its thin, uniform, and tough characteristics, does not require dressing due to clogging, and in super-finishing, new abrasive surfaces are continuously supplied at a constant speed to ensure stable processing without unevenness" in surface roughness.

The super finishing equipment can be used for both non-oscillating and oscillating finishing, and can produce both straight lines and cross hatches on the finished surface to achieve the desired finish.

Super finishing to enhance surface flatness

Film abrasives are highly flexible and fixed abrasive, which prevents dust formation and provides a good working environment.

The required accuracy can be easily obtained by selecting the film.