Do you have any of these problems??

1I'm concerned about the buff scum.

2Unable to obtain constant polishing roughness

3Life is short

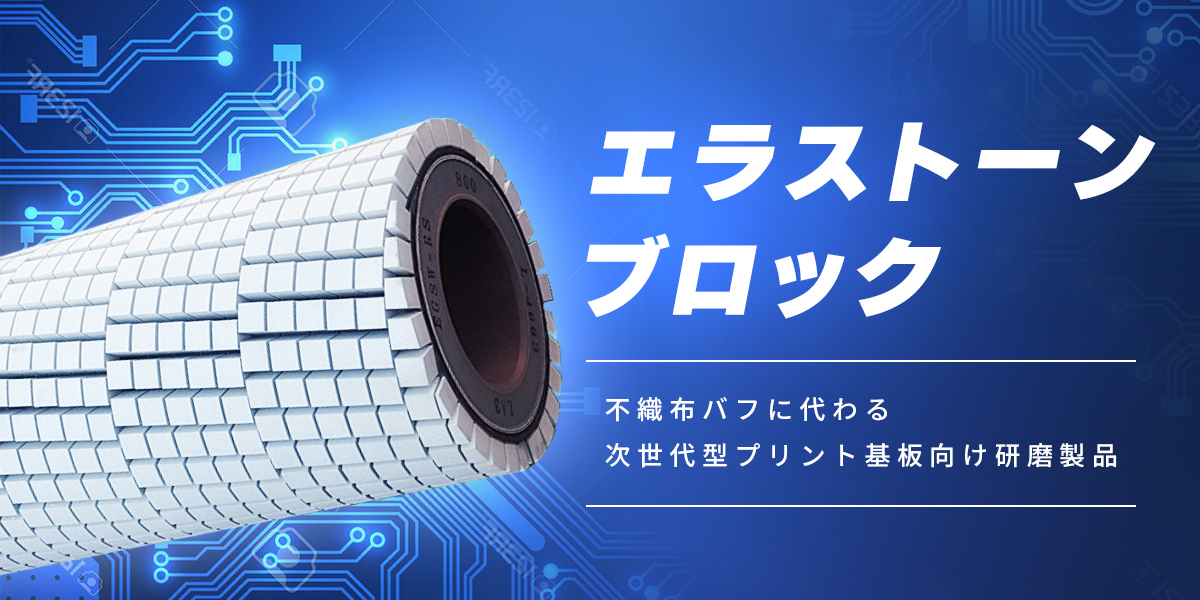

Elastic grindstone ERASTONE

will solve all your

problems.

will solve all your

problems.

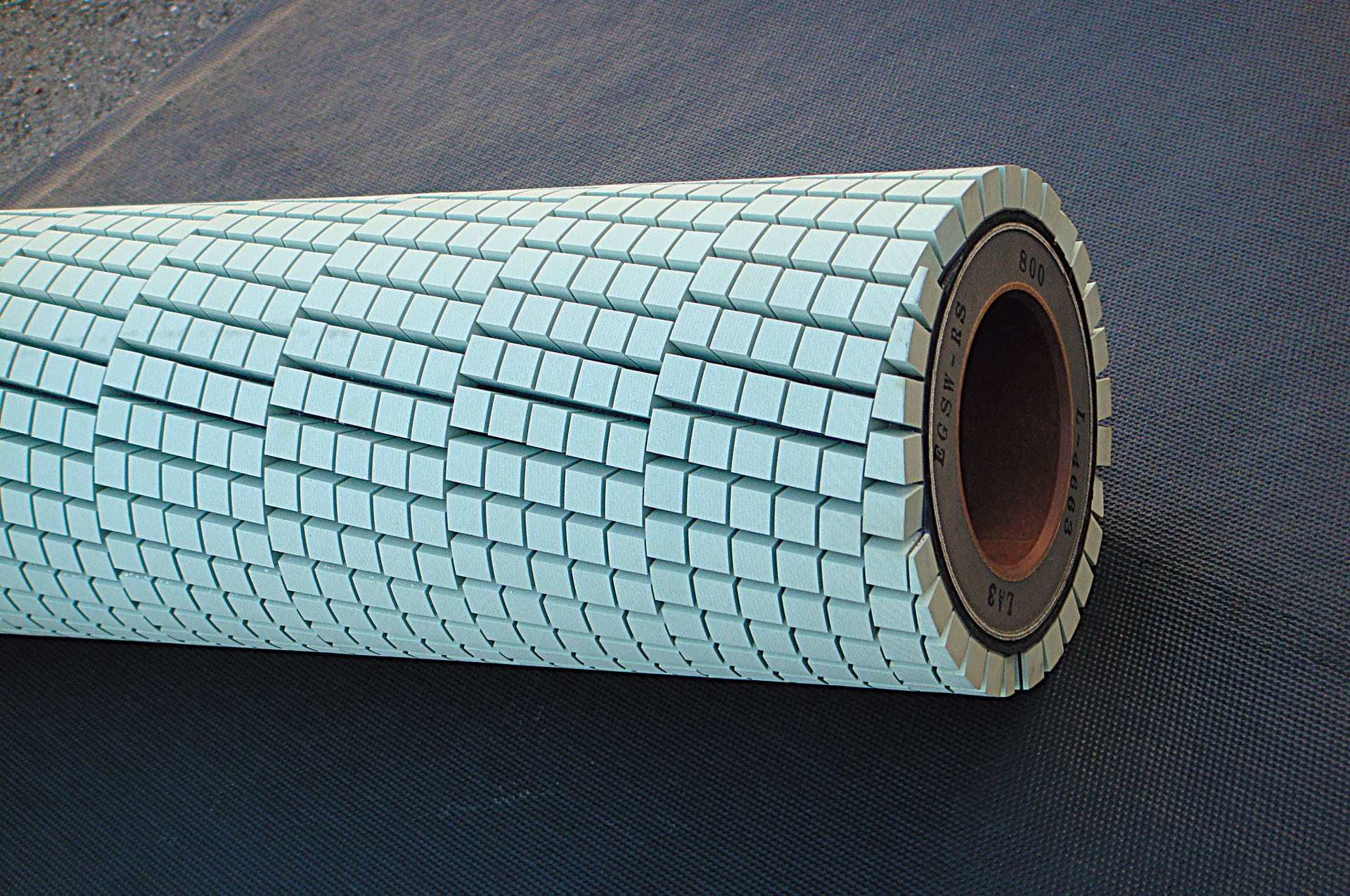

What is Elastic Grinding Wheel ERASTONE?

This is a completely

new type of "next-generation printed circuit board polishing product"

invented by Sankyo Chemical Co.

new type of "next-generation printed circuit board polishing product"

invented by Sankyo Chemical Co.

ERASTONE contains abrasive grains in rubber-modified synthetic resin,

so there is "zero buffing debris"!

Polishing without deep scratches, which has been a problem with conventional non-woven buffs, can be achieved.

so there is "zero buffing debris"!

Polishing without deep scratches, which has been a problem with conventional non-woven buffs, can be achieved.

Effects of Elastic Grinding Wheel ERASTONE

Buffcas Zero

~New materials solve the problems of conventional nonwovens~

Excellent tracking performance

~Follows as well as conventional nonwovens~

Product life

~Contributes to up to 2x waste reduction~

※ vs. General Nonwoven Buffing Products

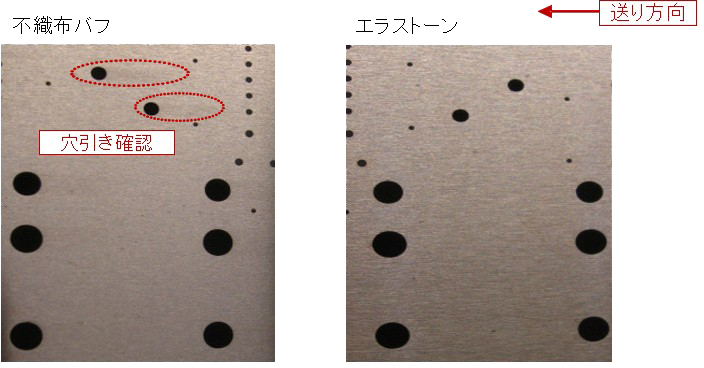

Comparison of buffing shavings during polishing

Nonwoven buffing

Ella Stone

buffcass

nil occurrence

nil occurrence

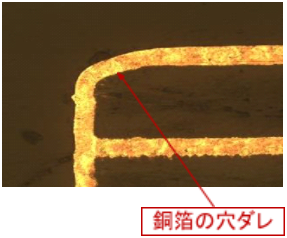

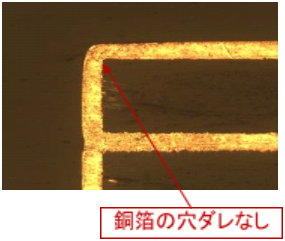

Comparison of buffing shavings hole clogging condition

Nonwoven buffing

Ella Stone

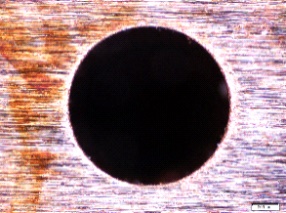

Cross section of through-hole after surface preparation and polishing

Nonwoven buffing

Ella Stone

Surface of pre-plated substrate after polishing hole burrs

Elastic Grinding Wheel ERASTONE Lineup

| (taxonomical) form | durometer | characterization | #240 | #320 | #400 | #600 | #800 | #1000 | #1200 |

|---|---|---|---|---|---|---|---|---|---|

| EGSW-RS | low | Long life type | ● | ● | ● | ● | ● | ● | |

| EGSW-RH | medium | Standard type | ● | ● | ● | ● | ● | ● | |

| EGSW-RG | high | High grinding type | ● | ● | ● | ● | ● | ● |

| (taxonomical) form | durometer | characterization |

Before plating Hole burr removal |

After plating whole face |

Before Solder Resist whole face |

fill-in ink (Ceramic buffing post-processing) |

fill-in ink |

|---|---|---|---|---|---|---|---|

| EGSW-RS | low | Long life type | #240-#600 | #400-#800 | #400-#800 | #600-#1200 | - |

| EGSW-RH | medium | Standard type | #600-#800 | #600-#800 | - | - | #240-#600 |

| EGSW-RG | high | High grinding type | - | - | - | - | #240-#600 |

We can provide products for various polishing types of non-woven buffs.