What is metal polishing? Tips for mirror polishing of iron What is the method of mirror finishing that revives to a shiny luster?

Do you have metalware with rust or stains?

Rust and dirt will make it look old-fashioned at once.

However, metal can actually be polished to restore its shiny luster.

In this article, we will briefly discuss metal polishing and mirror finishing.

Table of Contents

1. What is metal polishing? Mirror Finish is Needed to Revive Steel to a Shiny Luster

2. What metals are subject to polishing? Can mirror polishing restore the shiny luster of iron?

3. How to revive steel to a shiny luster with mirror polishing? Tips for Metal Polishing (Preparation of thesurface - Gloss (Mirror Finish))

4. Notes on Mirror Finish Polishing of Metals! Revive steel to a shiny luster without fail!

5. Polish the metal to a mirror finish and enjoy the revived shiny luster!

1.What is metal polishing? Mirror Finish is Needed to Revive Steel to a Shiny Luster

The following types of metalworking expressions are similar to "metal polishing".

・cut:Processing that removes large unnecessary portions and brings them closer to the desired shape.

・grind:Processing that slightly removes the metal surface to create the desired shape.

・polishing:Processing to smooth the surface by pressing abrasive material under constant pressurepolishing.

This section describes mirror finishing, one of the finishes of polishing.

2.What metals are subject to polishing? Can mirror polishing restore the shiny luster of iron?

What do you think of when people say "metal"?

Perhaps not a few people think of iron as a typical metal.

It is easy to imagine the iron reflecting and shining like a mirror.

In fact, however, metal is not inherently a shiny material.

This luster is just one of the metal's performance attributes imparted by the polishing process.

What is metal in the first place?

《Definition of Metal》

Metal is a generic term for a substance that is malleable, plastic (ductile), machinable, a good conductorof electricity and heat, and has a characteristic luster called metallic luster.

This is a little confusing, so let me explain briefly.

《Four major characteristics of metals》

・Deforms when pressure is applied 《Expandable》.

・Deforms when stretched 《plastic (ductile)》

→Easy to process

・Good conductor 《Heat conductor》 that easily conducts electricity and heat

・Metallic luster that reflects light when polished

If you organize it this way, you can probably think of many things in your daily life.

For example, when you put a steel frying pan on the fire, it heats up quickly and you can fry an egg, or you cansee your figure in your new stainless steel kitchen sink... These properties of metal are utilized in numerousareas of life.

However, there are many types of metals, from base metals such as iron and copper to precious metals such asgold and silver used for accessories, and alloys such as brass and stainless steel.

These metals such as iron and stainless steel can of course be polished to a shiny mirror finish.

In the next chapter, we will discuss tips and methods for mirror finishing metal.

3.How to revive steel to a shiny luster with mirror polishing?

Tips for Metal Polishing (Preparation of the surface - Gloss (Mirror Finish))

Next, the metal polishing method is described.

【Step1】 preparation of the surface

【Step2】 leveling

【Step3】 Polishing (mirror finish)

A glossy mirror finish can be achieved through these three processes. The following is a detailed explanation ofeach process.

1)preparation of the surface

If there is rust or dirt on the metal surface, we will remove them.

Abrasive materials are used at this time.

There are various types of abrasive materials, with paper and cloth files being the most common and relativelyeasy to obtain.

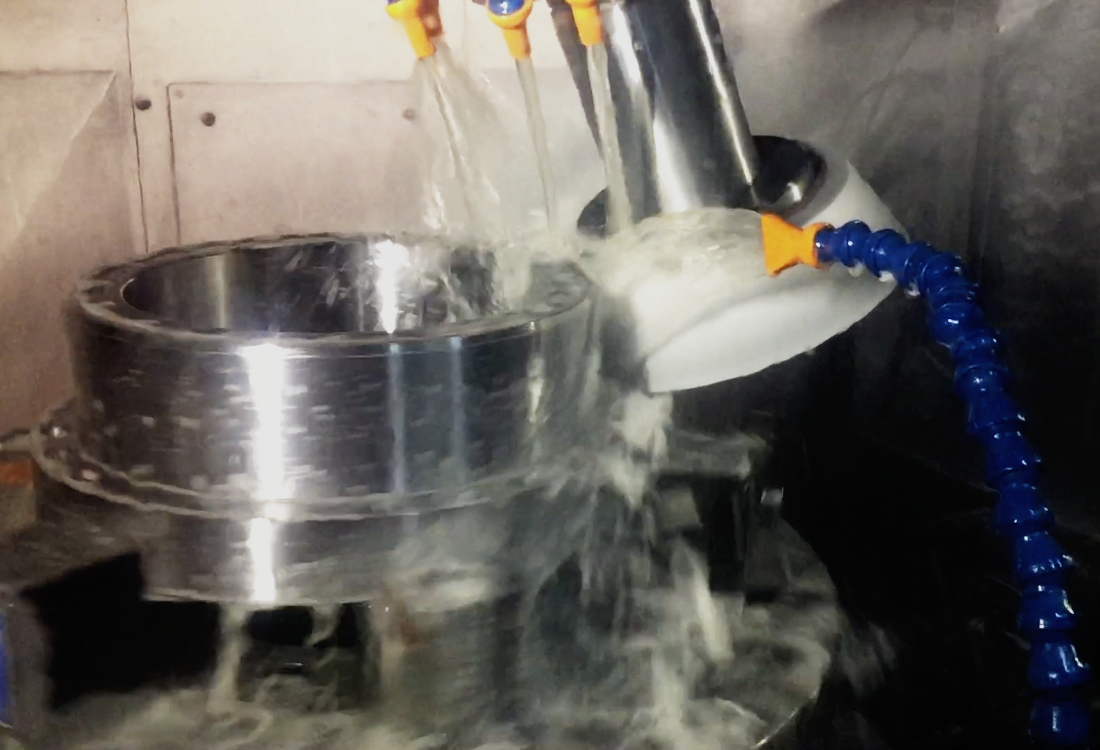

Others are in the form of belts or rolls and are attached to machines.

It is important to select the most suitable abrasive by looking at the size and shape of the target metal.

If the polishing is less uneven and over a smaller area, a paper or cloth file is a good choice.

Next, consider the grit size (number) of the abrasive.

Abrasives are available in a wide range of grit sizes, with the larger the number, the finer and moreprecise the finish.

In the basecoat stage, it is advisable to select a relatively coarse abrasive of about 3 grit sizes(number).

First, test polish the least noticeable area with the finest grit (grit number) of the three selected grit sizes(grit numbers).

This process finds the appropriate grit size (number) to remove rust and dirt.

Furthermore, by checking the degree of rust and dirt while scraping, it is possible to prevent excessivescraping.

At this time, be careful not to select an abrasive that is too coarse.

Deep scratches on the surface require more time to reach the final mirror finish.

《Points to keep in mind when preparing the substrate: Select a grit size (number) of abrasive that matchesthe degree of rust and stains.

2)leveling

Once all rust and stains have been removed, the next step is to polish the surface with a finer grit (number).

Apply the abrasive so that the abrasive scratches evenly over the entire object.

This is a very important process because the ability to grind evenly affects the final finish.

Gradually, the grain size (count) used is increased to finer and finer surface finishes are achieved.

《The key to eye-handling》 The abrasive is evenly applied to the entire surface to be polished.

3)polishing(Mirror finish)

The last step is polishing (mirror finish).

The last step is glazing.

While paper or cloth abrasives have been used in the polishing process, liquid abrasives such as compounds areused in the glazing process.

The particles are even finer than those of paper or cloth abrasives, and they will fine scratches on metalsurfaces.

Take a small amount of compound on a cotton cloth and spread it on the object to be polished.

Polish the entire surface in a wipe-off manner while extending the compound.

If the compound is spread over a large area at once, the compound will dry before polishing or wiping.

If the polishing area is large, it is recommended to use a small amount of compound and work in portions.

Once completely wiped down, check the surface condition and repeat this process until a mirror-like surface isachieved.

Use compounds of different grit sizes as needed to achieve a mirror finish.

《Point of polishing (mirror finish)》Compound should be used in small quantities and polishing should be repeated in parts.

4.Notes on Mirror Finish Polishing of Metals! Revive steel to a shiny luster without fail!

Since the character for "polish" is used in the word "kakushi" (polish), we tend to associate it with the ideaof "polish = to remove scratches,

Basically, abrasives themselves do not act to fill scratches (some compounds contain ingredients that have ahole-filling effect).

Polishing replaces irregular deep scratches with more uniform and fine ones.

Therefore, if too coarse an abrasive is used in the preparation stage, the substrate will be deeply scratchedand it will take longer to finish to a mirror surface.

It is important to select an abrasive grit size (number) that is appropriate for the degree of rust and dirt onthe substrate.

When aligning abrasives, it is safe to align one grit size (number) before and after the desired grit size(number).

Sankyo Rikagaku handles a full range of products related to polishing.

Please feel free to contact Sankyo Rikagaku about polishing.

ABRASIVE PRODUCTSPOLISHING MACHINECONTACT US

5.Polish the metal to a mirror finish and enjoy the revived shiny luster!

In this article, we have detailed the metal polishing process.

Through these processes, rusty or dirty metal can be made to look so shiny and mirror-like.

Although it takes some time, the process itself is relatively simple, so why don't you polish the things aroundyou to a shine?

If you are interested in polishing, please feel free to contact Sankyo Rikagaku.