What is metal hairline processing? Difference from mirror finishing process and merits and demerits of applying surface treatment

The beauty of the shiny, well-polished mirror finish is amazing, isn't it?

Certainly the beauty of a mirror finish is exceptional, but look around at the metal products around you.

Have you noticed that there are actually not as many shiny, mirror-polished items as you might think?

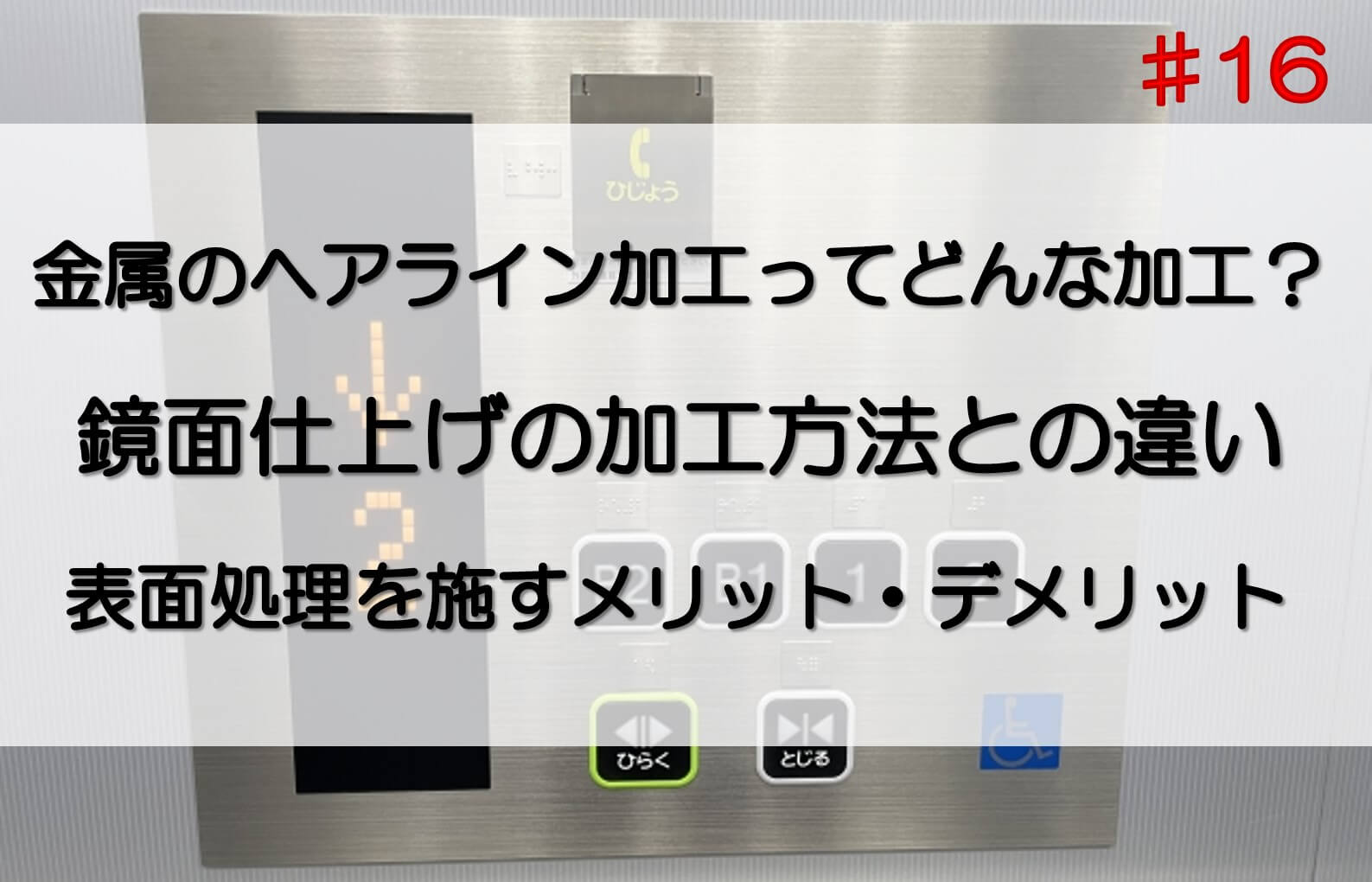

For example, doorknobs and elevator control panels are slightly rough rather than mirror-finished. Window sashesare also not mirror-finished.

Mirror finishes are supposed to be shiny and good looking, but do you know the two main reasons why mirrorfinishes are not used on these products?

Table of Contents

1. Shiny polished mirror finish is beautiful but actually not often employed!

What is the purpose of metal surface treatment?

2. What is a hairline finish? Actually, it has many advantages!

Why is the hairline finish applied by polishing surface treatment?

3. What kind of polishing method is best for hairline processing?

What is the best way to do hairline finishing for surface treatment of metals and resins?

4. If it is a surface treatment by metal polishing such as hairline processing

Leave it to Sankyo Rikagaku Co!

5. Polishing metal and resin surfaces creates opportunities to create new value!

1. Shiny polished mirror finish is beautiful but actually not often employed!

What is the purpose of metal surface treatment?

While mirror finishing has great advantages as a processing method, such as improved appearance, it has twomajor weaknesses.

Weaknesses of mirror finish on metal (1)

Requires skillful techniques and a lot of working time to finish the metal to a mirror finish.

Mirror finishing requires three processes: preparation of the surface, normalizing, and glazing.

Not only does it take a lot of time to polish the workpiece to a mirror surface, but it also requires skill toensure that the polishing grit from the previous process is removed over the entire workpiece area.

Weaknesses of mirror finish on metal (2)

Minor scratches on the metal mirror surface should be quite noticeable.

It is even possible to hit something at some point.

Minor scratches are inevitable as long as they are used on a regular basis.

This is especially true for items that are used on a daily basis, such as computers and smartphones, as well asfor doors, sashes, and other home fixtures that are difficult to replace.

It would be cool if there were smartphones and laptops with mirror-finished bodies, but there is another pitfallhere.

Fingerprints!

Because of the smoothness of the mirror finish, oil adherence is easily noticeable in the form of fingerprints.

Indeed, no matter how mirror-finished and glossy the body may be, if it is prone to fingerprints, it willrequire frequent cleaning, making it impractical.

For these reasons, a finish that is not only aesthetically pleasing but also practical is more useful than amirror finish.

In other words, this processing method is resistant to scratches and stains that covers the weakness of mirrorfinish and can be easily applied.

The solution to this problem is a processing method called hairline processing.

Let's learn about the hairline finish this time.

2. What is a hairline finish? Actually, it has many advantages!

Why is the hairline finish applied by polishing surface treatment?

The hairline finish, also described as H L finish, has the greatest feature of being less likely to show minorscratches and more versatile.

Because of its versatility, it is used in a wide range of products, including housing equipment, electronics,jewelry, and medical devices.

In the hairline process, a fine line of scratches is applied to an object in a fixed direction. The name"hairline" means,

It is believed to originate from the characteristic fine linear pattern that looks like hair.

Scratches, however, are fine and uniform, so the unique texture of the metal is retained, while the matt effectis achieved, creating a sense of high quality.

For this reason, they are often applied to watches and other jewelry.

The hairline process itself is a so-called general-purpose process used for surface treatment of manymetals,

Among the many metals, it is probably most often applied to stainless steel.

One reason is that stainless steel is more resistant to rust and tarnish than copper or iron, so it can maintainits hairline texture for a long period of time.

Advantages of Hairline Finish on Metal

・Scratches and stains are less noticeable

・Less machining time

・Possible to process many materials

On the other hand, there are some disadvantages of the hairline finish.

While it is effective in making scratches in the hairline direction less noticeable, it is not effectivefor scratches in the hairline direction and perpendicular to the hairline direction.

Another disadvantage is that the hairline pattern fades over time.

Disadvantages of Hairline Finish on Metal

・Scratches perpendicular to the hairline direction are more noticeable.

・Hairline pattern fades with age.

3. What kind of polishing method is best for hairline processing?

What is the best way to do hairline finishing for surface treatment of metals and resins?

How is the hairline process performed on metal?

The most common method of hairline processing is to apply it by continuously grinding in a fixed direction witha belt grinder.

Polishing a surface in a fixed direction with an abrasive belt produces a straight polishing line.

There are various types of hairline processing, and it is possible to create different textures by changing thegrain size (number) of the abrasive belt.

In general, hairline processing is performed by polishing with a grit size (#150 to #240).

4. For surface treatment of metals by polishing, such as hairline processing, leave it to Sankyo RikagakuCo!

Among Sankyo Rikagaku's abrasives, we recommend the following items for surface treatment.

When it comes to metal polishing, this is what we call it! The standard cloth belt

Recommended Product 1: Resin Cross Belt (Sankyo Rikagaku Co.)

ABRASIVE PRODUCTSCONTACT US

Cloth belt with zirconia grit for excellent sharpness!

Recommended Product 2: Gilbert. (Sankyo Rikagaku Co.)

In fact, metal surface treatment methods are not limited to the hairline finish introduced here,

One such example is the "nashiji" (pear-shaped) finish that we have posted on our blog before!

You can read our previous articles on the Nashiji process here!

There are many advantages to pear-finishing of metals! How does it work with plating? What is the pearfinish method for stainless steel?

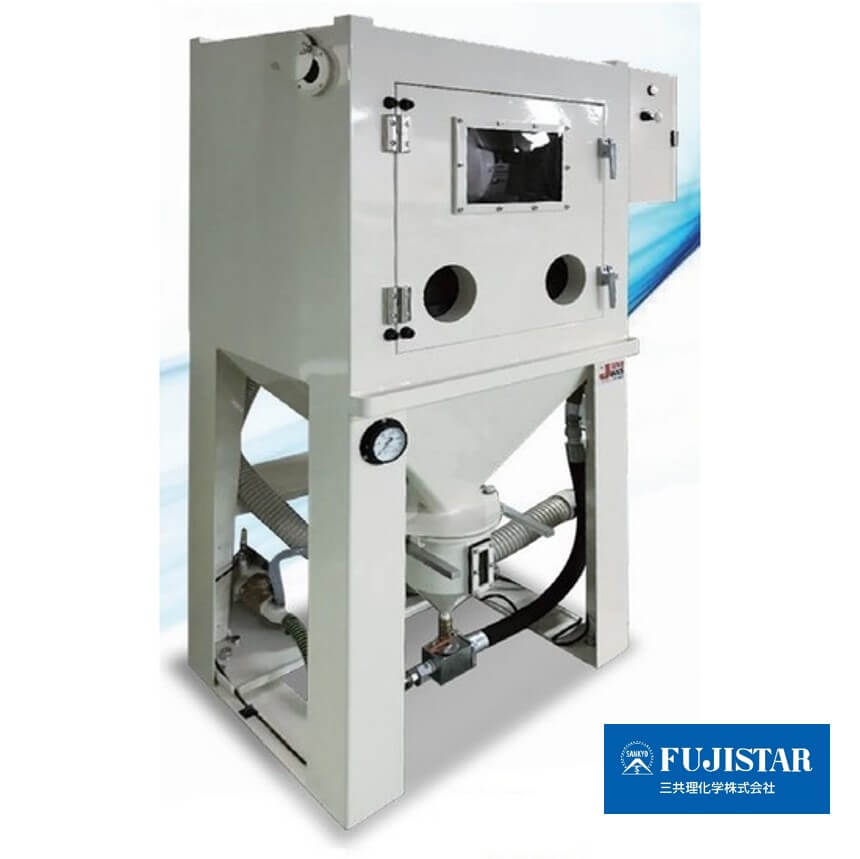

Sankyo Rikagaku's Blasting Equipment Recommended for Pearskin Finish on Metal - Effective for PearskinFinish on Stainless Steel

Recommended Product 3: Blasting equipment (Sankyo Rikagaku Co.)

Sankyo Rikagaku's blasting equipment can process even complex shapes of treated surfaces.

The finish can be freely controlled by varying the type of projectile (media), ejection speed, andpressure.

In addition, the system is compatible with automation, so it is not dependent on operators and can bemanufactured to the required quality.

5. Polishing is used for surface treatment of metals and resins,

Opportunities to create new value are created!

Surface treatments such as the hairline process introduced here can create high added value by improvingappearance and functionality.

There are various types of surface treatments, including the pearskin finish and mirror finish introducedpreviously.

Each has its own characteristics, and it is important to select the appropriate treatment method according tothe material, purpose, and application.

Since polishing technology is used in many surface treatment methods, we recommend that you carefully observethe objects around you and consider what kind of treatment is being used.

If you are interested in polishing or surface treatment, please contact Sankyo Rikagaku Co.