What is the grinding process and how does it differ from polishing? Advantages and disadvantages of the grinding process - What is the difference between grinding, cutting, and polishing? Let's know the meanings of the words for grinding and polishing! ~ part2 ~ What is cutting?

In the previous part 1, we introduced the following words related to grinding and polishing.

Grinding, polishing, cutting

Following on from in part 1, let's learn about grinding in this part 2.

Grinding is the process of rotating a grinding tool, such as a grinding wheel, at high speed to bring an objectto a designed size, shape, or target roughness.

A typical grinding tool used at this time is a grinding wheel.

Grinding stones are composed of abrasive grains, similar to common abrasive materials known as sandpaper.

The major difference from a sandpaper is that there is no base material (paper part in the case of a paper file)and the abrasive grains are solidified.

The abrasive grains contained in the grindstone become fine blades and play the role of scraping off minuteamounts of the object.

The self-sharpening action of the grinding wheel used in the grinding process maintains sharpness and allowsmachining of materials with hardnesses that are difficult to achieve with other processes, such as hardenedmetals and superalloys.

・Advantages of Grinding

High-precision machining (dimensional and roughness adjustment) is possible. Capable of machining hard materialsthat are difficult to machine with other machining methods, such as hardened metals and superalloys.

・Demerits of Grinding Process

Since the material is cut off in minute increments, processing time may be required depending on the area to becut off. In order to process efficiently, the shape must be prepared to some extent in the previousprocess,

It is necessary to use grinding to make fine adjustments.

Characteristics of Grinding Process - How is it different from Grinding and Cutting Processes?

As explained in part 1 grinding, polishing, and cutting are all removal processes (i.e., processes aimed at shaving off unnecessary parts).

However, they are actually used differently because the purpose of machining and its accuracy are different.Grinding does not involve the creation of shapes like cutting.

In other words, we do not grind so large that the shape changes. Grinding is applied to increase dimensionalaccuracy.

If further added value (improved appearance) or precision is required, polishing is performed as the finalfinishing process.

Different machining methods are used depending on the target dimensions and required accuracy.

What are the different types of grinding processes? Are there many methods like the grinding process?

Just as there were various types of grinding processes, there are several types of grinding processes aswell.

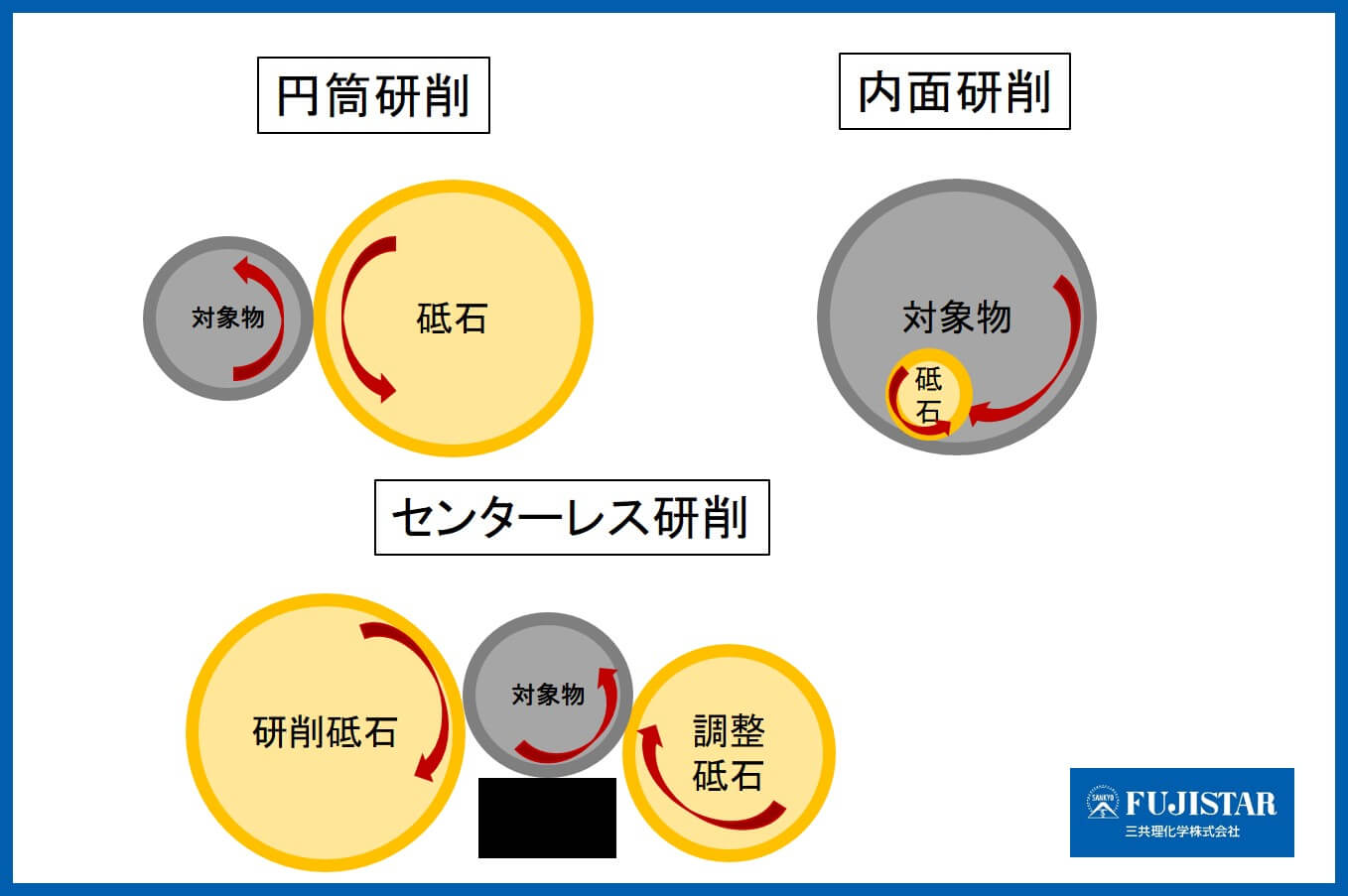

・Cylindrical Grinding

This is a machining method for grinding the outside of a cylindrical object.

In this process, the circular grinding wheel and the object each rotate in opposite directions to grind theoutside of the object.

・Internal Grinding

In internal grinding, the grinding wheels are placed inside the system and rotated in opposite directions sothat they strike the inner surface of the object.

When grinding the inside diameter of an object, it is necessary to use a grinding wheel smaller than the insidediameter.

・Centerless Grinding

This is a processing method in which the object is fixed with two types of rotating grinding wheels (grindingwheel and regulating wheel) and a support stand, and the outside of the object is ground.

Grinding is performed when the regulating wheel cuts in the direction of the grinding wheel.

There are several types of grinding processes, and it is necessary to use different methods depending on whichpart of the object is to be ground.

In this issue, we briefly explained what "grinding" is.

Although the terms seem similar, you may have noticed that there are differences in purpose and finish from therest of

In the next part3, we will introduce