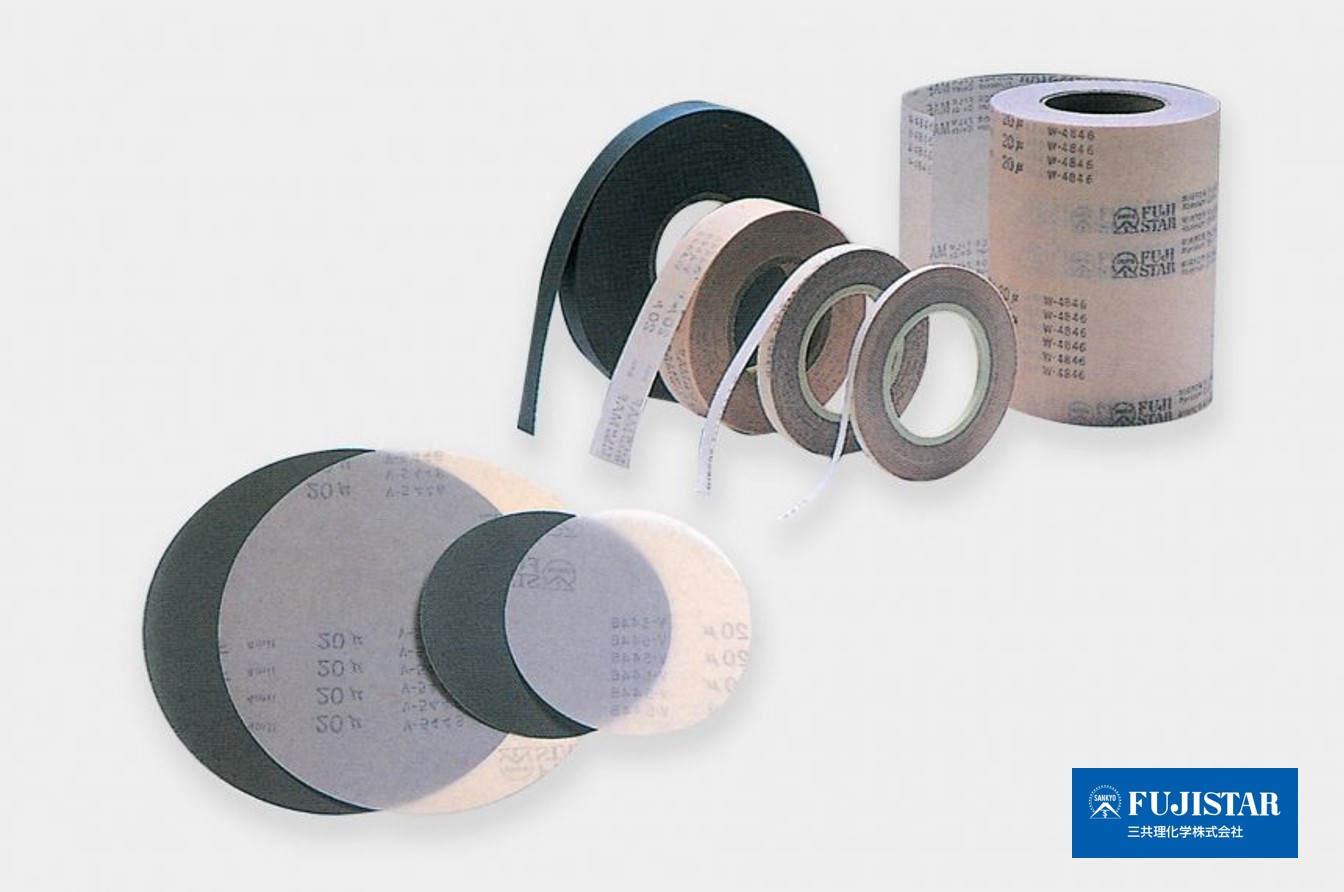

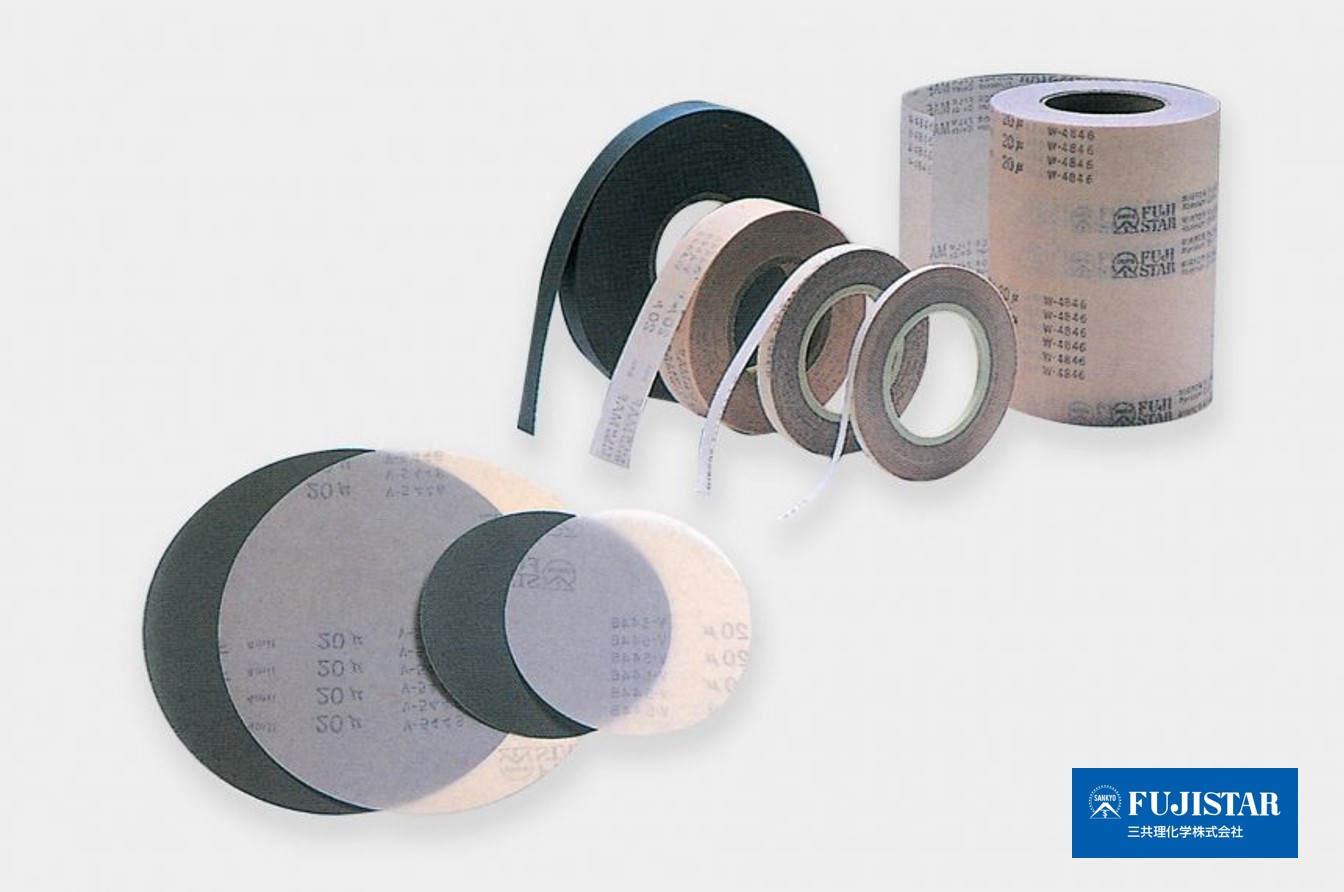

Sankyo Chemical's ultra-precision polishing products

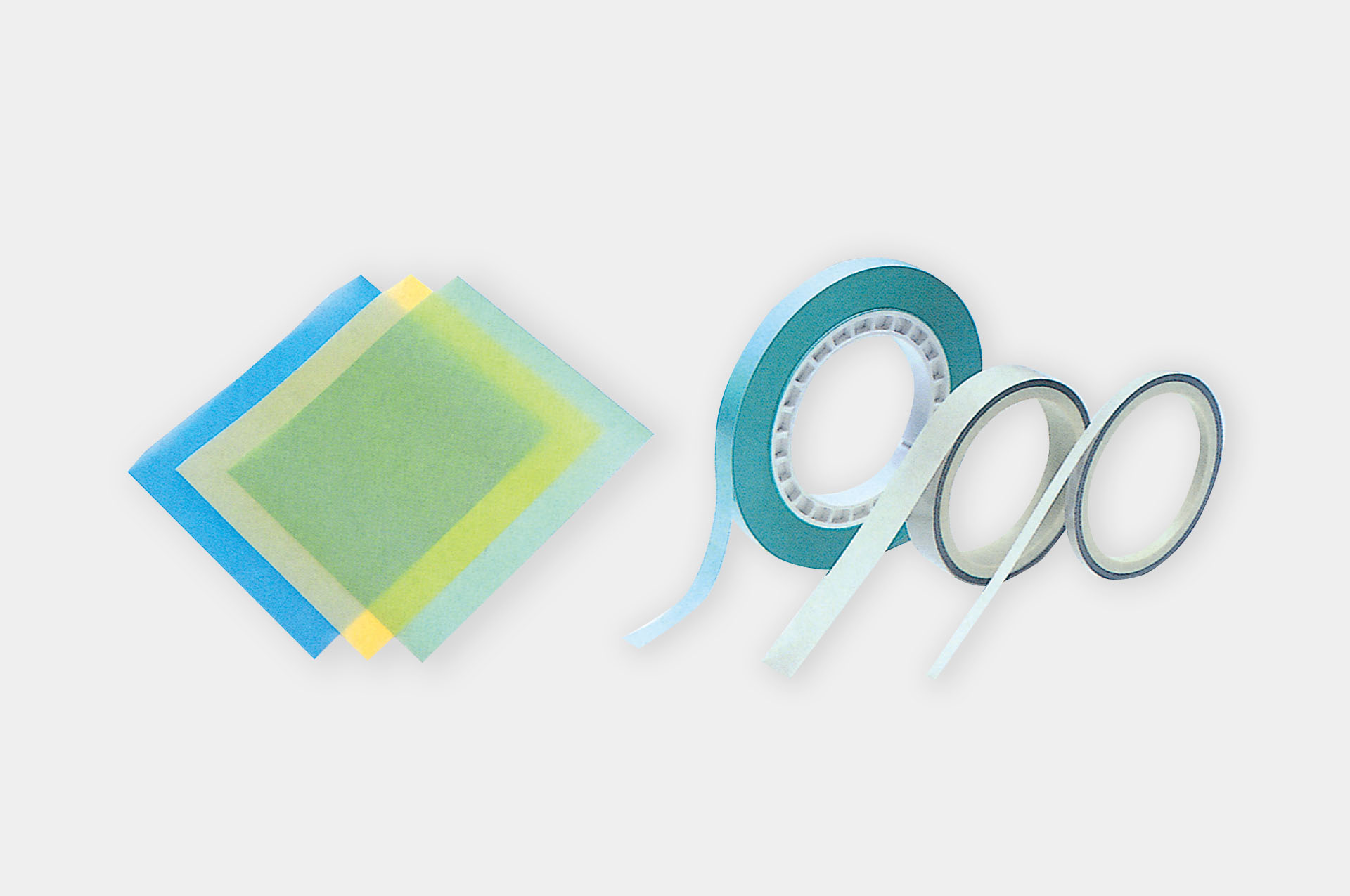

mirror film

What is Mirror Film?

Mirror film is coated with fine abrasive particles on a smooth film substrate to achieve a

high-precision finish that cannot be achieved with cloth or paper products.

- ◎ Excellent abrasiveness and durability.

- ◎ Precise, uniform surfaces can be obtained efficiently and more easily.

lapping film

What is lapping film?

Lapping film is coated with uniformly dispersed ultrafine abrasive particles to provide a

uniformly finished surface without deep scratches.

- ◎ Both dry and wet films can be used, and the film can be selected according to the required accuracy.

- ◎ Abrasive grains are dispersed in resin, enabling even more precise finishing than with mirror film.

Sankyo Chemical Films

substrate

Uniform in thickness, smooth and tough, polyester film is a base material that resists tension

and tearing with minimal expansion and contraction.

Continuous automatic polishing by mechanization is possible, and stable surface finish can be obtained.

Available in thicknesses from 25 μm, it can also be used for work on curved surfaces that require flexibility.

Continuous automatic polishing by mechanization is possible, and stable surface finish can be obtained.

Available in thicknesses from 25 μm, it can also be used for work on curved surfaces that require flexibility.

Abrasive grain

To accommodate a wide variety of materials, we offer a lineup of products coated with aluminum

oxide (WA abrasive), silicon carbide (C abrasive), and diamond abrasive particles. The particle

size can be selected from a wide range, from 100 μm to 0.1 μm.

Diamond lapping film is especially suited for precision polishing and finishing applications for high-hardness materials, difficult-to-machine materials such as ceramics and ferrite, fragile materials, and new materials.

Diamond lapping film is especially suited for precision polishing and finishing applications for high-hardness materials, difficult-to-machine materials such as ceramics and ferrite, fragile materials, and new materials.

adhesive

Highly durable in dry or wet polishing with water- and oil-resistant adhesives.

Why Choose Us

Sankyo Chemical can provide solutions to finish your workpieces to the desired surface roughness.

With an extensive lineup of abrasives, we can pursue the desired finish by selecting the abrasive that

best suits the customer's workpiece.

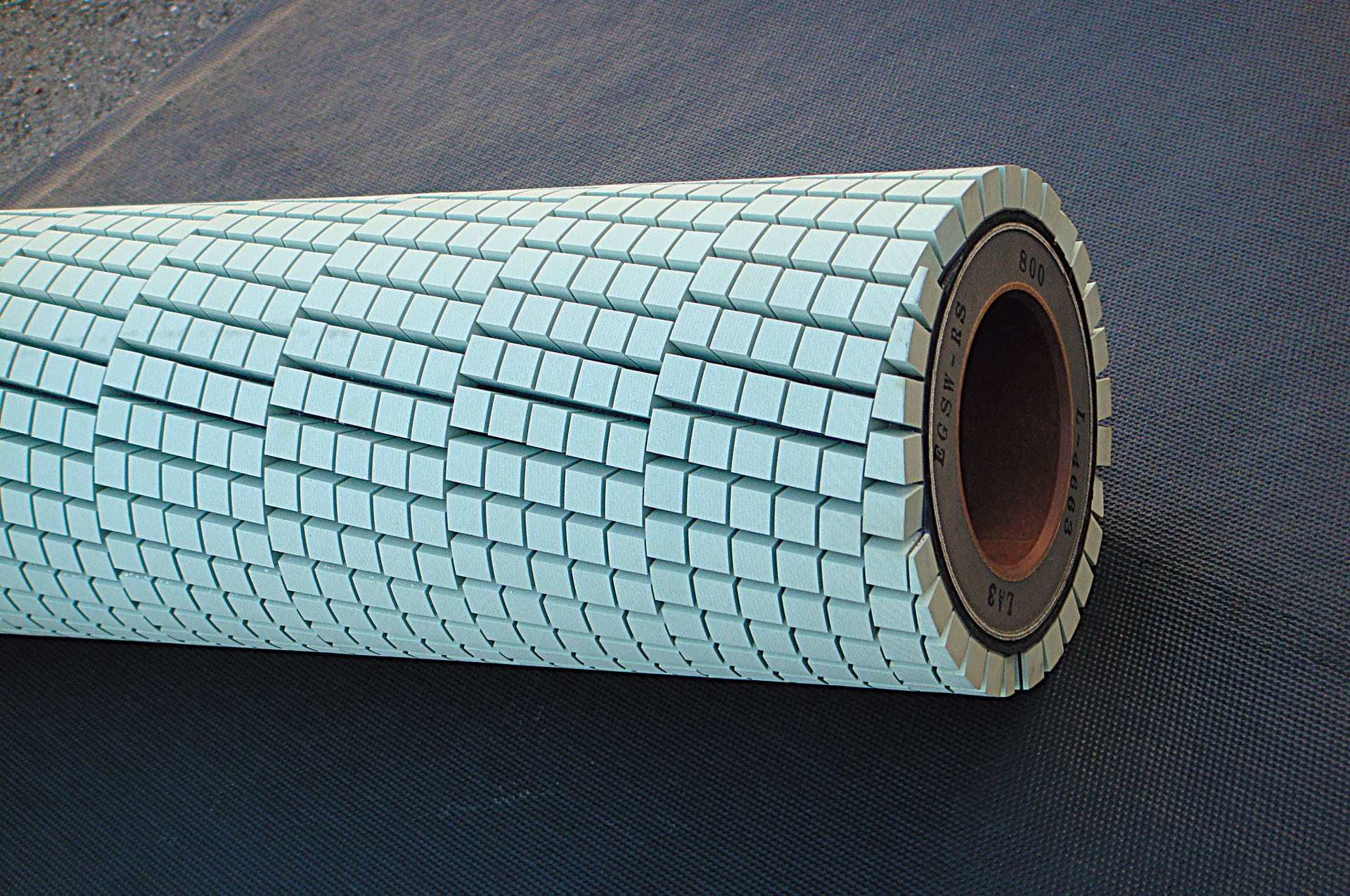

Sankyo Chemical's films are a perfect match for automation!

For example, a polishing system using precision polishing film can match the roughness set without destroying the shape of the workpiece.

Super-finishing by continuous feeding is possible, which not only stabilizes quality but also improves machining efficiency and is far easier to control than wheel grinding.

Super-finishing and polishing of inner and outer diameters can also be entrusted to us.

Sankyo Chemical's films are a perfect match for automation!

For example, a polishing system using precision polishing film can match the roughness set without destroying the shape of the workpiece.

Super-finishing by continuous feeding is possible, which not only stabilizes quality but also improves machining efficiency and is far easier to control than wheel grinding.

Super-finishing and polishing of inner and outer diameters can also be entrusted to us.

Q&A

Q: What is continuous supply?

A: Because a new polished surface is continuously supplied at a constant speed, the surface roughness is

not uneven and stable processing is possible.

◎ Advantages of Polishing with Fixed Abrasive Grains

Not only does this facilitate process control and shorten working hours, but it also improves the work environment by preventing the generation of dust.

Not only does this facilitate process control and shorten working hours, but it also improves the work environment by preventing the generation of dust.

◎ Supports backside processing

Non-slip type is also available to suit roll and belt grinders.

Non-slip type is also available to suit roll and belt grinders.

Product Information

mirror film

| type | substrate | Abrasive grain |

substrate thickness |

granularity | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 120 | 240 | 320 | 400 | 600 | 800 | 1000 | 1500 | 2000 | 3000 | ||||

| MAF | Film | WA | 75μ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||

| 100μ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |||||

| 125μ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |||||

| MCF | Film | CC | 100μ | ○ | ○ | ○ | ○ | ○ | |||||

| 125μ | ○ | ○ | ○ | ○ | ○ | ○ | |||||||

| VAF | Film | WA | 125μ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| VCF | Film | CC | 125μ | ○ | ○ | ○ | ○ | ○ | |||||

| SAF | Film | WA | 125μ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||

| DAF | Film | WA | 100μ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |||

| DCF | Film | CC | 100μ | ○ | ○ | ○ | ○ | ○ | ○ | ||||

| SDF | Film | Diamond | 100μ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||

lapping film

| type | substrate | Abrasive grain | substrate thickness | granularity | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 320 | 400 | 600 | 800 | 1000 | 1500 | 2000 | 3000 | 4000 | 6000 | 8000 | 10000 | 20000 | ||||

| LWF | Film | WA | 25μ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| 75μ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||

| LGF | Film | GC | 75μ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||

| LCF | Film | CC | 25μ | ○ | ○ | ○ | ○ | |||||||||

| 25μ | ○ | ○ | ○ | ○ | ||||||||||||

| LDF | Film | Diamond | 25μ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||

| 75μ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||