Abrasive that smoothly

removes machining marks

and fine burrs in all

polishing processes

removes machining marks

and fine burrs in all

polishing processes

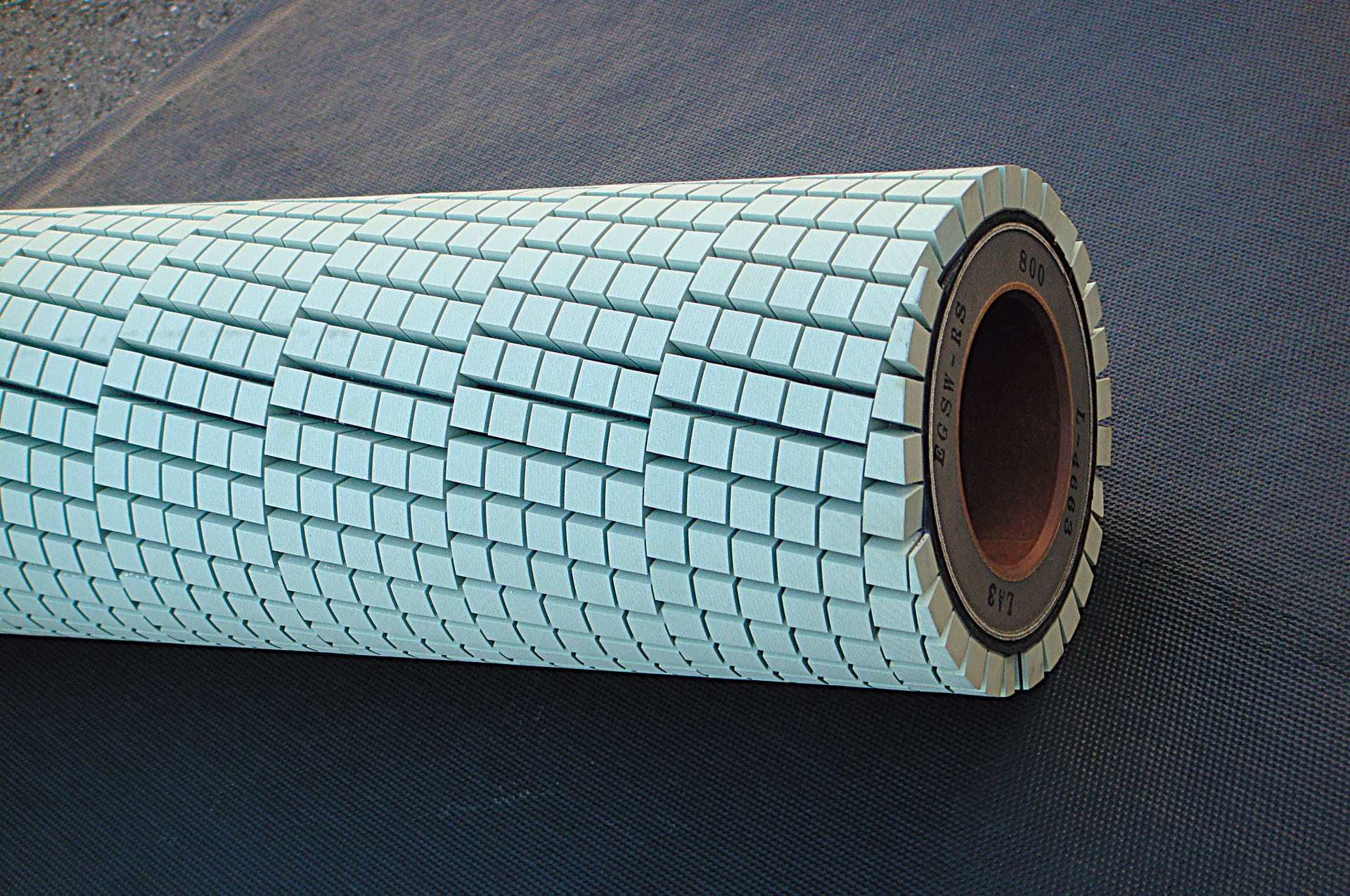

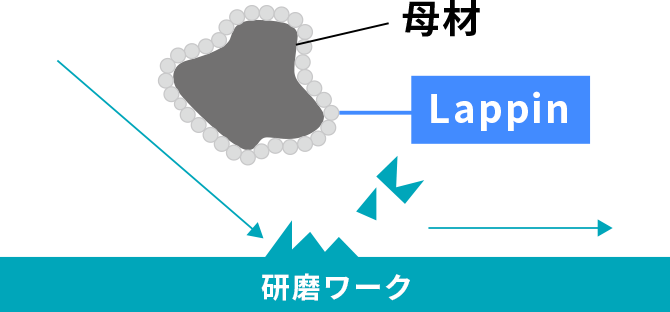

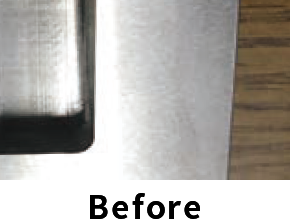

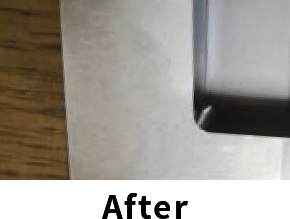

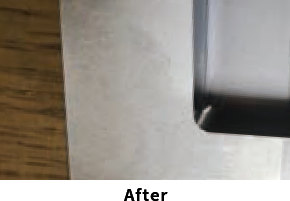

Lappin is an abrasive originally developed by Sankyo Chemical

that can remove machining marks and fine burrs without damaging the underlying material.

Blasting with fine abrasive grains removes machining marks, fine burrs, and surface film.

that can remove machining marks and fine burrs without damaging the underlying material.

Blasting with fine abrasive grains removes machining marks, fine burrs, and surface film.

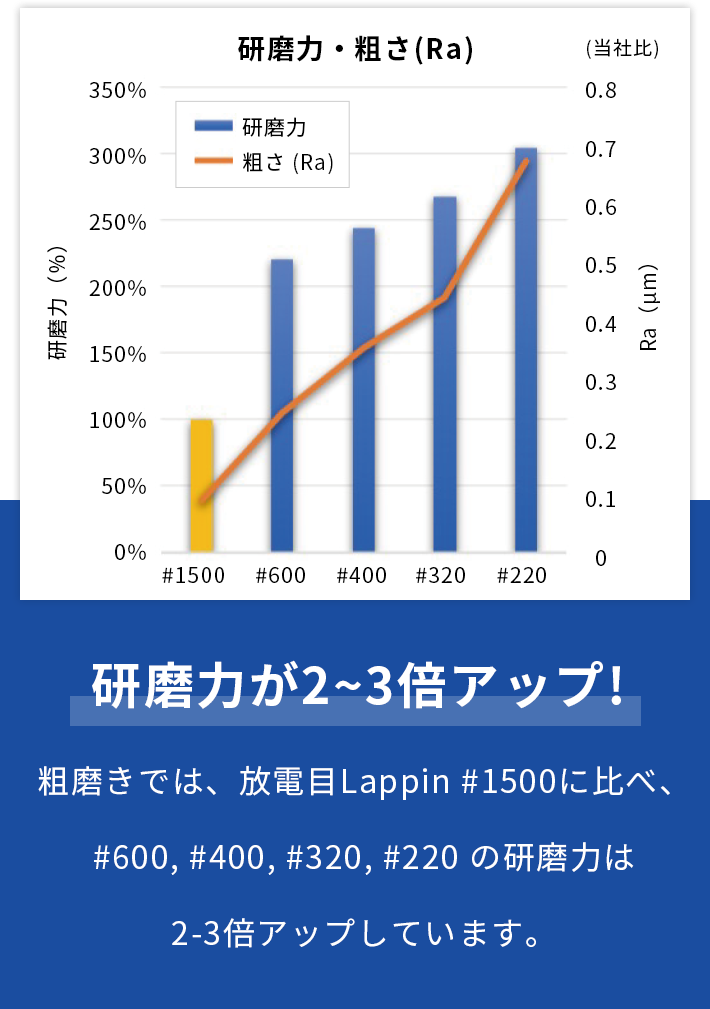

Supports a wide range of polishing processes from rough polishing to finishing

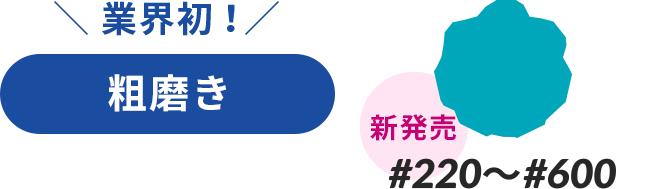

An industry first! Newly released abrasives

that are effective for "rough polishing," which requires the most man-hours.

Significantly reduces the time required for polishing.

that are effective for "rough polishing," which requires the most man-hours.

Significantly reduces the time required for polishing.

Wide range of particle sizes available for all polishing processes

shape

○

Average particle size

0.65mm

granularity

silicon carbide (SiC):#220~#8000

diamond:#1500~#10000

diamond:#1500~#10000

shape

Average particle size

granularity

○

0.65mm

silicon carbide (SiC):#220~#8000 diamond:#1500~#10000

Supported materials

SKD、SKH、NAK、

high-speed steel、STAVAX、

SUS、aluminum (Al) etc

high-speed steel、STAVAX、

SUS、aluminum (Al) etc

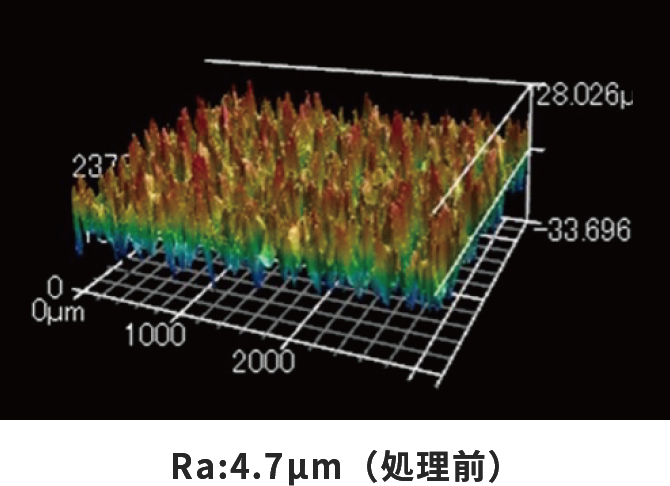

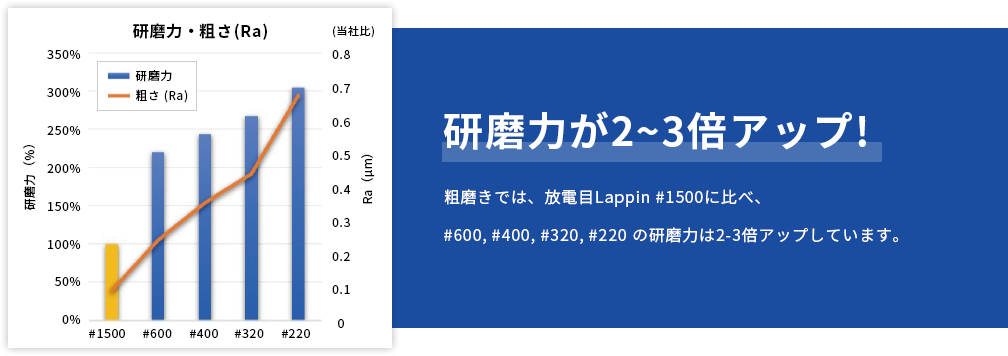

Effects of

"Rough Polishing" as seen in data

"Rough Polishing" as seen in data

Rough polishing reduces the man-hours required

to remove the discharge eye.

to remove the discharge eye.

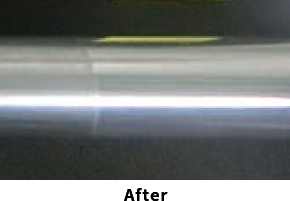

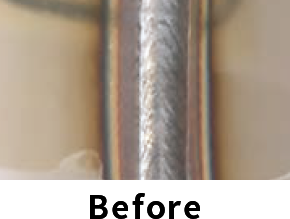

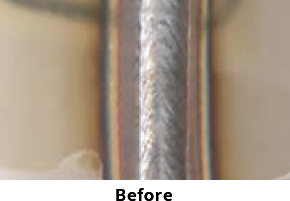

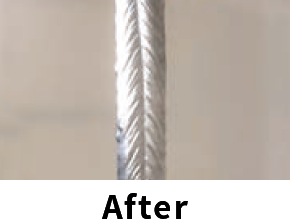

Data on surface condition after mold polishing treatment

(When processed at #220)

(When processed at #220)

LappinFeatures

Will not damage the substrate!

Elastic media is soft and removes only fine burrs without damaging the underlying material

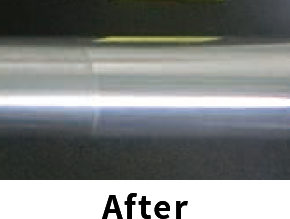

High polishability!

Blasting with fine abrasive grains to remove machining marks, fine burrs and surface film and improve surface finish

Any device can be used.!

Air blasting equipment can be used with either blower or compressor systems, and abrasives only can be sold.

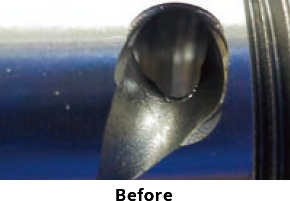

processingexample

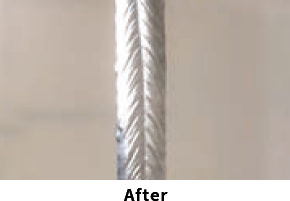

Microdeburring

polish

Weld Burn Removal

Removal of machining items

Recommended Polishing Equipment

Lappin is sold as a stand-alone product, but dedicated polishing equipment is also available.

Blower type blast polishing equipment dedicated to Lappin

The direct pressure type doubles the projection volume! The blower type is overwhelmingly recommended for customers considering initial introduction and automation!

Excellent with abrasive special media "Lappin".

Excellent with abrasive special media "Lappin".

Designed to slide off special media "Lappin" for easy circulation

Turntable and barrel type as well as additional functions such as robotization and in-line support are possible.

All ancillary equipment such as blowers, dust collectors, and operation panels are built into the equipment and can be used only with a 200 V power supply.

One-touch construction for attaching and detaching the abrasive tank by opening and closing the lever

AB-1-LAP type

| Equipment type | AB-1-LAP type | |

|---|---|---|

| Air source | tool blower | AC200V 50/60HZ 2.2KW |

| Discharge pressure | 40~60KPa | |

| ON-OFF | Foot Pedal Type | |

| blast (from explosion) | nozzle | μ10 |

| Abrasive tank | 3 liters | |

| Abrasive material adjustment | Manual Ball Valve | |

| Abrasive material input | Automatic ball valve | |

| interior lighting | LED | |

|

dust collector |

output (e.g. of dynamo) | AC200V 50/60Hz 0.2KW |

| Maximum air intake | 1.2㎥/min | |

| filter (esp. camera) | Cyclone Molding Filter | |

| external dimension | width 670mm x Depth 880mm x Height 1620mm | |

| Cabinet Dimensions | width 600mm x Depth 600mm x Height 450mm | |

Compressor type

Dedicated to Lappin

Blast Polishing Equipment

Dedicated to Lappin

Blast Polishing Equipment

Continuous operation and low heat generation! Overwhelmingly recommended for renewal, compressor type!

We will set the conditions for you even if you use "Lappin".!

We will set the conditions for you even if you use "Lappin".!

Designed to slide off special media "Lappin" for easy circulation

Turntable and barrel type as well as additional functions such as robotization and in-line support are possible.

All ancillary equipment such as blowers, dust collectors, and operation panels are built into the equipment and can be used only with a 200 V power supply.

One-touch construction for attaching and detaching the abrasive tank by opening and closing the lever

AB-1-SAM type

| Equipment type | AB-1-SAM(SAM-6) type | |

|---|---|---|

| Air source | compressor | 3.7KW(not included in the price) |

| Discharge pressure | 0.3~0.7MPa | |

| ON-OFF | Foot Pedal Type | |

| blast (from explosion) | nozzle | Air µ3 Blast µ6 |

| Abrasive material adjustment | Needle type | |

| interior lighting | LED | |

|

dust collector |

output (e.g. of dynamo) | AC100V 50/60Hz 0.2KW |

| Maximum air intake | 4㎥/min | |

| filter (esp. camera) | Bug filter | |

| external dimension | width 650mm x Depth 700mm x Height 1560mm | |

| Cabinet Dimensions | width 650mm x Depth 500mm x Height 600mm | |

Experience the unprecedented

effects of Lappin,

a special media that

can be sharpened and polished.!

effects of Lappin,

a special media that

can be sharpened and polished.!