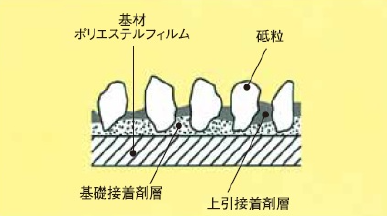

Mirror film

Mirror film is coated with ultrafine abrasive particles on an excellent smooth

film backing by electrostatic coating,

providing high precision, excellent polishability and durability

that cannot be obtained with cloth or paper products.

The film abrasive is thin, uniform, and tough, eliminating the need for dressing due to

clogging.

In super-finishing, new polished surfaces are continuously supplied at a constant speed to ensure

stable machining without surface roughness irregularities.

Use (Shape)

roll・・・Crankshafts, camshafts, flat displays, magnetic heads and disks

disk・・・Plastic lenses, optical fiber terminals, analysis sample pieces, magnetic

heads and disks, coating film polishing

sheet・・・Fiber optic terminal, analysis sample piece

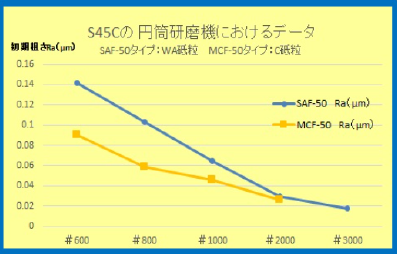

【Grinding data】

【Comparison of abrasiveness between WA abrasive and C abrasive】

WA abrasive has good grindability and long life, while C abrasive focuses on

finishing and does not cause deep scratches.

VAFs are colored differently depending on the grain size to prevent

misidentification.

Abrasive grain type: WA (white arundum oxide) CC (carborundum) D (diamond)

Base material: 75µ = 3 mils 100µ = 4 mils 125µ = 5 mils