Refine environmental performance.

Kind to people and the environment… We believe this is essential for the company.

Always be aware of and practice our responsibility as a manufacturer to reduce all kinds of burdens on workers and on living infrastructure such as electricity and water supply.

Sankyo Rikagaku is a company that is constantly striving to improve its environmental performance in consideration of people and the global environment.

We, SANKYO RIKAGAKU, are a people-friendly…『polish』

SANKYO RIKAGAKU's Approach

Quality・environment・Safety and Health Policy

Based on our vision of "Creating the world with polish," we will expand our business both domestically and internationally with the aim of contributing to society.

- In order to provide satisfaction and peace of mind to our customers, we apply a management system based on ISO9001 and strive to continuously improve quality and develop innovative solutions that create new value.

- We will set and work on goals to improve the quality of our products and operations by promoting technological development and improvement activities.

- Continuously improve the applicable QMS processes to achieve the expectations, needs and requirements of our customers and stakeholders.

- We apply EMS based on ISO14001, strive to continuously improve our environmental performance, comply with environmental laws and regulations, and aim to prevent pollution.

- To leave a better environment for future generations, we will promote greening activities and thoroughly manage and reduce energy consumption, emissions, and industrial waste.

- Under the slogan of "Safety Extraordinariness," we aim to achieve zero lost time injuries through the participation of all employees by adhering to the established rules.

- We continuously improve the work environment to maintain and improve the health and safety of our employees.

June 30, 2022

SANKYO RIKAGAKU Co.President and Representative Director Kyoko Fujiya

Download PDF fileReduction of CO2 emissions at Okegawa Plant・Major Energy Conservation Initiatives

| May 2006 | Boiler fuel changed from heavy oil to city gas |

|---|---|

| April 2008 |

Natural gas and engine cogeneration system installed As part of our environmental preservation activities, a new natural gas cogeneration facility was installed at the Okegawa Plant, one of our production bases, and started operation on May 1, 2008. This has resulted in a 10% reduction in energy consumption for the entire plant, contributing to energy conservation, and by using natural gas, which is said to be clean, we are further promoting the creation of a plant that is friendly to the global environment and reduces environmental burdens. Approximately 72% of the plant's total annual electricity consumption is supplied by this system, making it possible to prepare for power supply risks. |

| July 2009 | Introduction of new lines and elimination of obsolete lines |

| January 2013 | Renewal of air compressors, factory lighting, etc. through ESCO project |

※These and other efforts, together with energy conservation, have contributed significantly to CO2 emissions reduction, with a 24.6% reduction compared to the 6% energy-derived CO2 emissions target of Saitama Prefecture's Global Warming Countermeasures Promotion Ordinance.

About ISO

ISO standards, which are internationally accepted standards, set forth international standards for products and services to "ensure that the same quality and level of quality is provided throughout the world" in order to facilitate international trade.

-

ISO

14001

E M S Date of establishment

2003

October 10In addition to reducing energy and resource consumption, which contributes to environmental preservation, we aim to create an environmentally friendly environment in the manufacturing and distribution processes of our products.

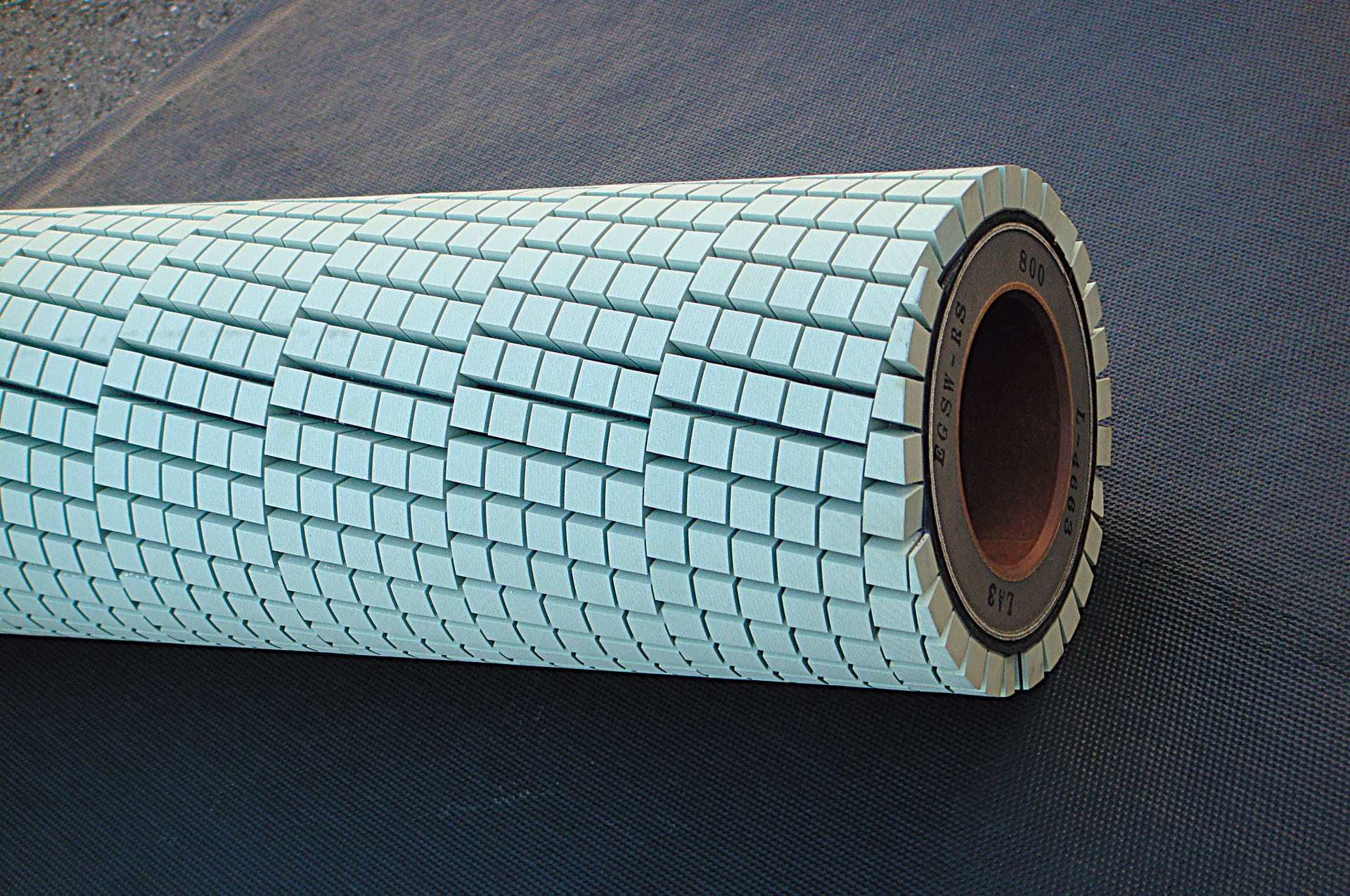

scope (of a document) Product Abrasive cloth and paper, abrasive products, abrasive machinery (e.g., blasting machine)

activity R&D, manufacturing, processing, and sales operations for abrasive cloth paper, and maintenance and repair operations for manufacturing facilities

Service Outsourcing of product processing, product delivery, machinery manufacturing, incinerator operation, waste disposal, fuel transportation

※ EMS = Environmental Management System

-

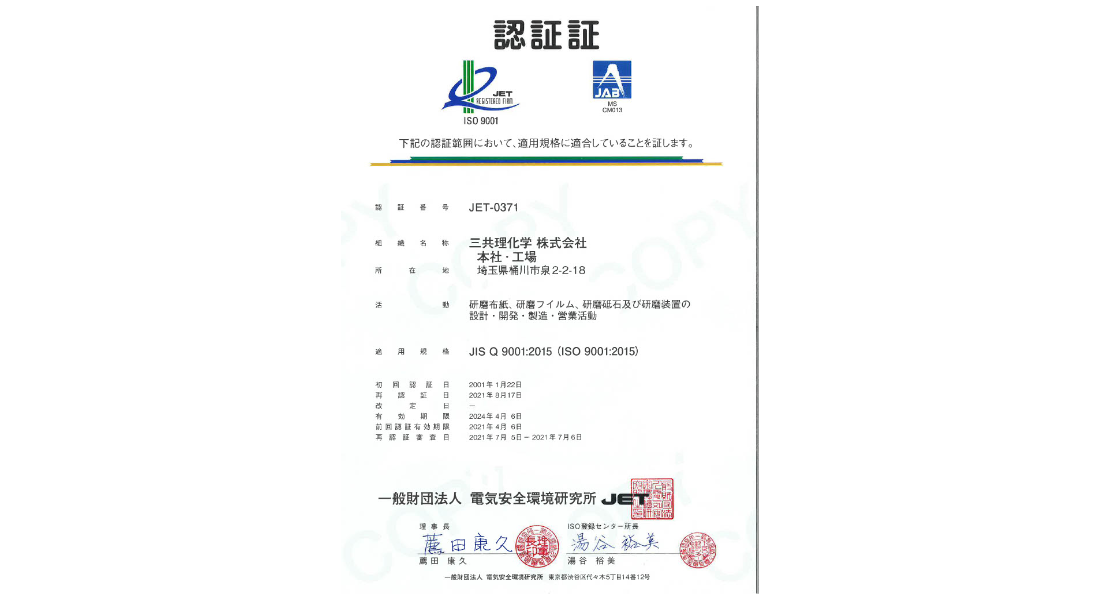

ISO

9001

Q M S Date of establishment

2001

January 22.We are committed to providing quality products that earn the trust and satisfaction of our customers.

※ QMS = Quality Management System

Public announcements regarding maintenance and management of general waste treatment facilities

Information on the maintenance of general waste treatment facilities in accordance with the Waste Disposal and Public Cleansing Law will be published on this page.

Maintenance data for general waste treatment facilities (incineration facilities) PDF:227KB