Is polishing necessary before painting metal? Reasons and Advantages of Painting Metals

With the recent demand for nest eggs, many of you may have started creative hobbies such as DIY and plastic modeling.

The texture of metal is so massive and fascinating that it is often compared to the iron style in DIY projects.

However, bare metal surfaces are vulnerable to rust and scratches, and may not be suitable for long-lasting use in a clean condition.

Painting is the solution to such problems!

These days, there are many easy-to-purchase painting kits available at home centers, so perhaps the hurdle to painting is lower than it used to be.

In fact, painting can expand the range of metal utilization to a whole new level!

In this issue, we will discuss the role and methods of polishing in the pretreatment of paint.

Table of Contents

1. Is it necessary to polish metal or resin before painting?

2. Reasons for polishing before painting and benefits of surface preparation

3. What is needed for the method of polishing before painting and what are the precautions for polishing

4. 3 recommended abrasives for polishing before painting.

5. Polish metal and resin before painting to improve the finish!

1. Is it necessary to polish metal or resin before painting?

Do you

In fact,

It is not only against metals.

The same is true for wood, plastic and other resin coatings.

Even if the materials are different, the pre-treatment, "polishing," is an important factor that determines the finished product.

2. Reasons for polishing before painting and benefits of surface preparation

Why is polishing necessary when the substrate is immediately visible once painted?

In fact, simply painting does not guarantee that the coating will perform as expected (adhesion, corrosion resistance, etc.)!

Proper pretreatment (polishing) is necessary to maximize their functions.

The purpose of this polishing process is to make the surface to be painted smooth, free of dust and rust, and free of irregularities.

Polishing improves the surface condition and finish.

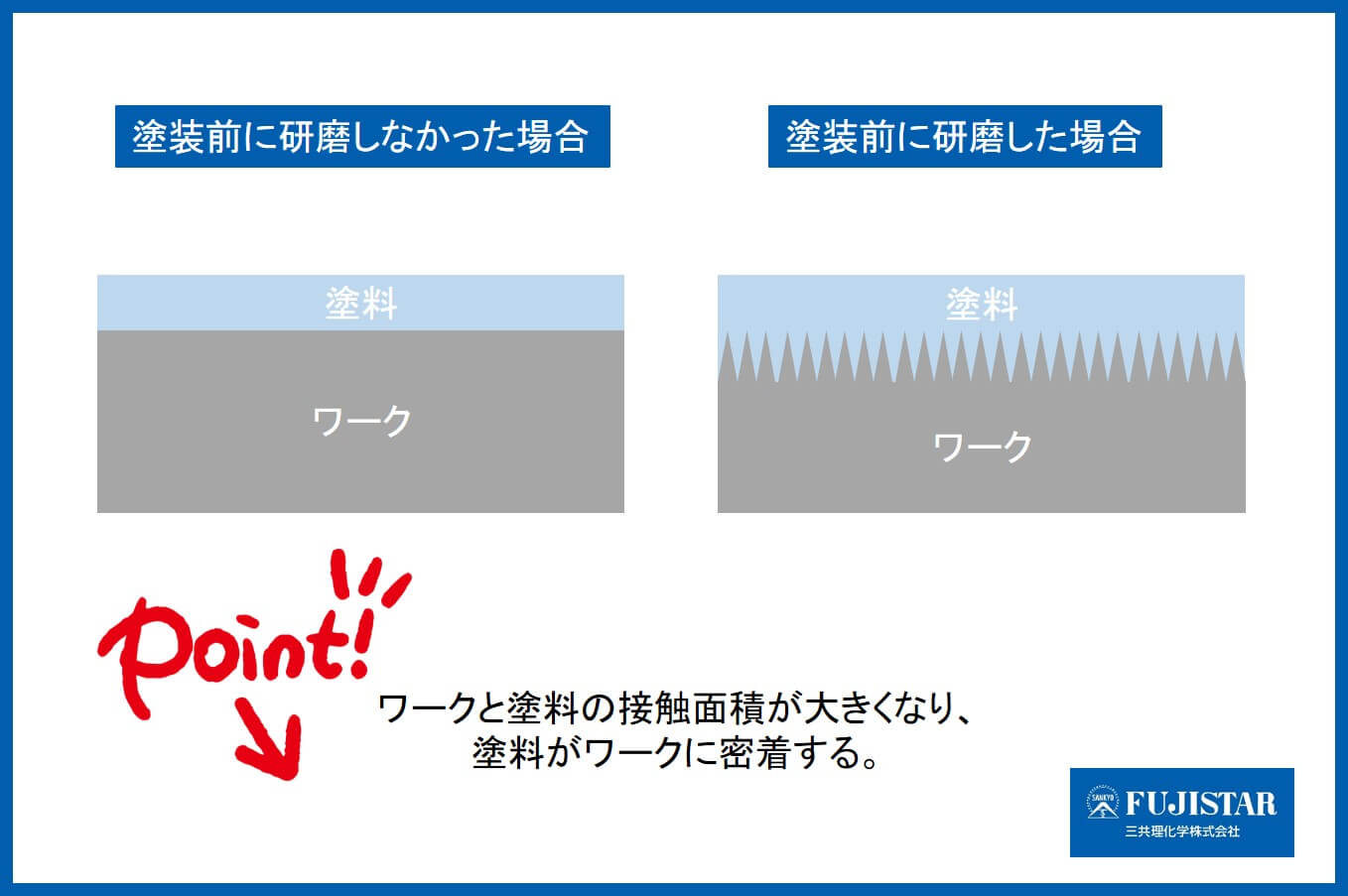

Also, by polishing and daring to scratch the painted surface, the adhesion of the paint is enhanced.

The higher adhesion naturally improves the durability of the coating film, and it can be expected to enhance the functional aspects of the coating, including rust prevention.

Polishing before painting has the advantage of improving the finish and functional aspects.

3. What is needed for the method of polishing before painting and what are the precautions for polishing

Having discussed the importance of polishing before painting, we will now explain the actual method, what to prepare, and precautions to take.

First, polishing before painting is called "Ashitsuke.

For footing, a "paper file" made of paper or a "cloth file" made of cloth is used.

Since there are different grades (grain sizes) of files, we will show you how to select one for each purpose.

Painting is usually finished through multiple processes.

In the case of a three-step process, the process consists of footing, the first coat of primer, footing again, the second coat of intermediate coat, and the third coat of topcoat after the last footing.

~Primer Coating~

・Surface is heavily soiled or uneven

・Old paint film remains

・Considerably rusted

In such cases, use #80 to #150 coarse abrasives.

Removing rust and dirt and stripping off old paint film requires a certain level of abrasive performance.

However, it should be noted that the higher the polishing performance, the deeper the scratches due to polishing will be.

Rust and dirt are also acceptable!

If the rust is removed properly, a beautiful paint film will be achieved!

Click here for easy rust removal

Can rust removal be done by polishing? Benefits and methods of rust removal.

・Surface is relatively smooth with little surface contamination or rust

In such cases, use #180 to #320 medium grit abrasives.

Medium grit abrasives are the most commonly used number for groundwork.

It can be used not only for priming but also for surface preparation prior to the middle coat.

~Middle and top coats~

For the middle and top coats, #400 to #600 fine abrasives come into play.

By repeating the process of footing + painting at each step, an even and uniform coating film can be obtained.

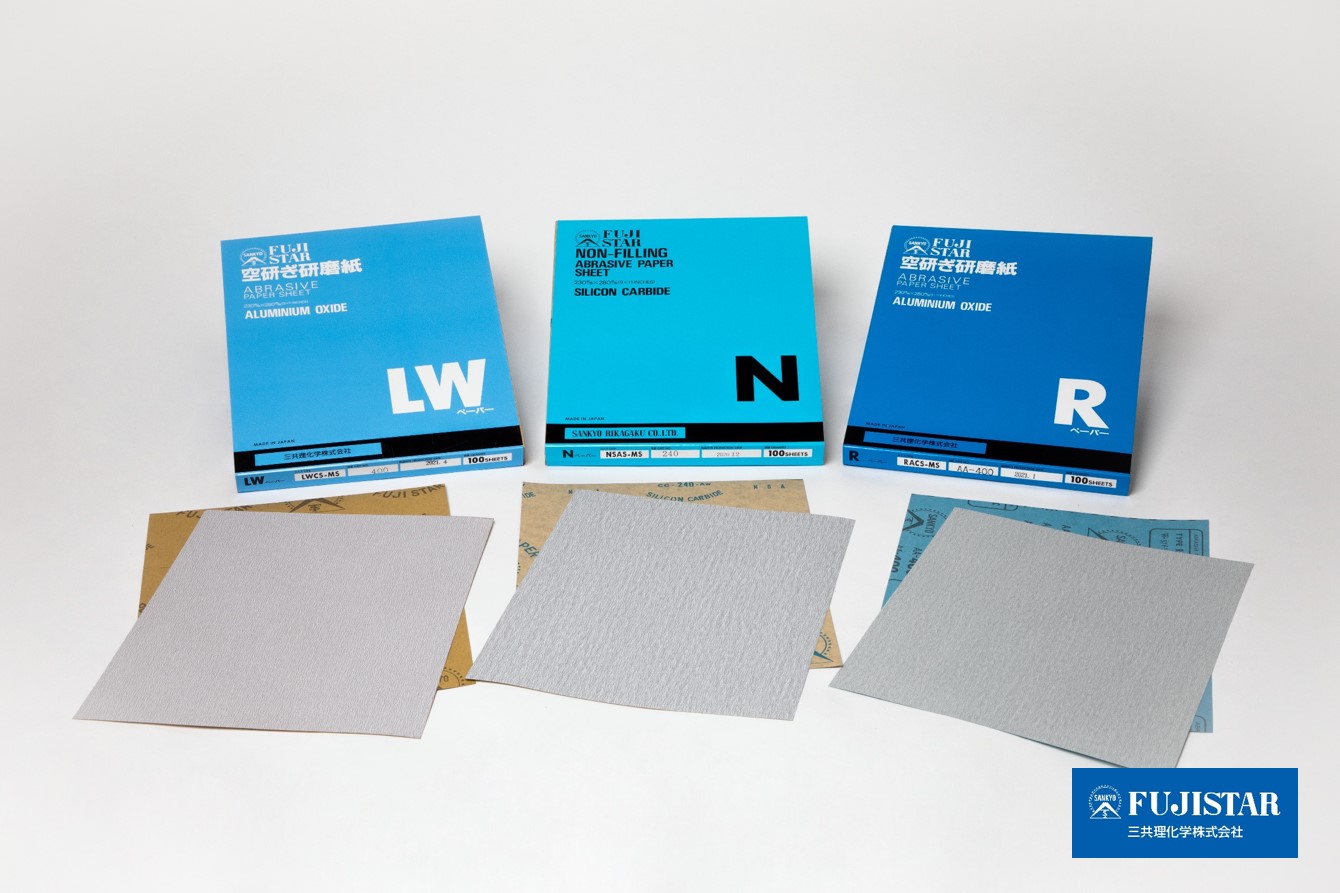

4. 3 recommended abrasives for polishing before painting.

Sufficient polishing performance for footing! Ideal for those who want to take care of dirt and uneven surfaces while also providing firm footing!

Recommended Product 1: Dry abrasive paper (Sankyo Rikagaku Co.)

Click here for product details

Contact us

Easy to use for resin and curved parts that are prone to clogging.

Recommended Product 2: Water Resistant Abrasive Paper (Sankyo Rikagaku Co.)

Click here for product details

Contact us

From persistent rust removal to footing, it is sure to be a great success!

Recommended Product 3: Kenmaron (Sankyo Rikagaku Co.)

The nylon non-woven fabric is coated with abrasive grains to maintain excellent grinding performance and prevent clogging.

Because of its excellent elasticity, it blends well even on curved surfaces.

It can also be used as a preparatory footing for painting, making it a perfect item for painting after rust removal.

Click here for product details

Contact us

If the paint is extensive, tool polishing is also recommended!

5. Polish metal and resin before painting to improve the finish!

In this issue, we talked about the importance of

Considering the purpose and carefully polishing with abrasives of the appropriate grit size (grain size) is a shortcut to a good finish.

When it comes to painting, we tend to focus on the application method and tools, but

Polishing will take more time for this process, but surely, you can expect a much better finish than if you had applied it as is.

If you are interested, please give it a try!

If you are interested in polishing or coating, please feel free to contact Sankyo Rikagaku.