What is cutting? Let's know the purpose and method of cutting process! ~What is the difference between grinding, cutting, and polishing? Let's learn the meanings of the words for grinding and polishing! ~ part3 ~ What is metal hairline processing?

In the previous part 2, we introduced

We hope you could sense the difference between this process and the

In the last part3, let's learn about the remaining

~ part3 What is cutting? Let's learn the purpose and method of cutting! ~Part 2

Cutting allows the use of specialized tools to make holes or grooves in an object.

The main purpose of cutting is to process the product to the shape and ideal size for the application.

It is also called "removal machining" because unnecessary parts are removed. Depending on the cutting method and special tools used, cutting is also referred to by different names, such as milling, turning, and drilling.

The advantage of cutting is the ability to process complex shapes in a short time.

There are many other advantages, such as the ability to process a wide range of materials.

We can process metals such as aluminum, stainless steel, and iron, as well as non-metals such as plastics and resins.

Furthermore, cutting is basically done one at a time, making it easy to produce small-lot production at low cost.

・Advantages of Cutting

① It is possible to process complex shapes in a short time.

② Can be processed with a variety of materials.

③ Small lot production can also be produced at low cost.

On the other hand, such cutting processes also have their weaknesses.

Because it is suited for small-lot production, mass production requires a lot of processing time and costs more.

・Demerits of Cutting

④Not suitable for mass production.

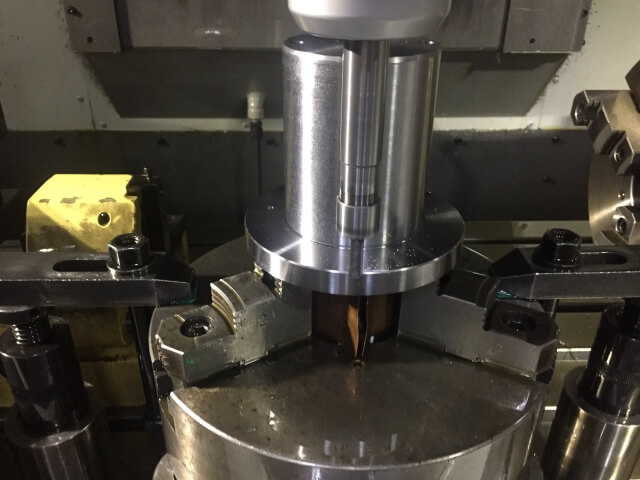

There are various types of specialized tools mentioned earlier, and one of the most well-known cutting tools is the bite.

The basic structure of a tool is divided into a cutting edge and a handle. The handle is fixed to the machine tool, and the cutting edge is brought into contact with the material for processing.

The material of the cutting edge includes cemented carbide, ceramics, sintered diamond, etc., and is selected according to the object to be machined.

What are the types of cutting operations? Tools Used in Cutting Processes

As explained earlier, cutting methods and tools differ depending on what shape the target is.

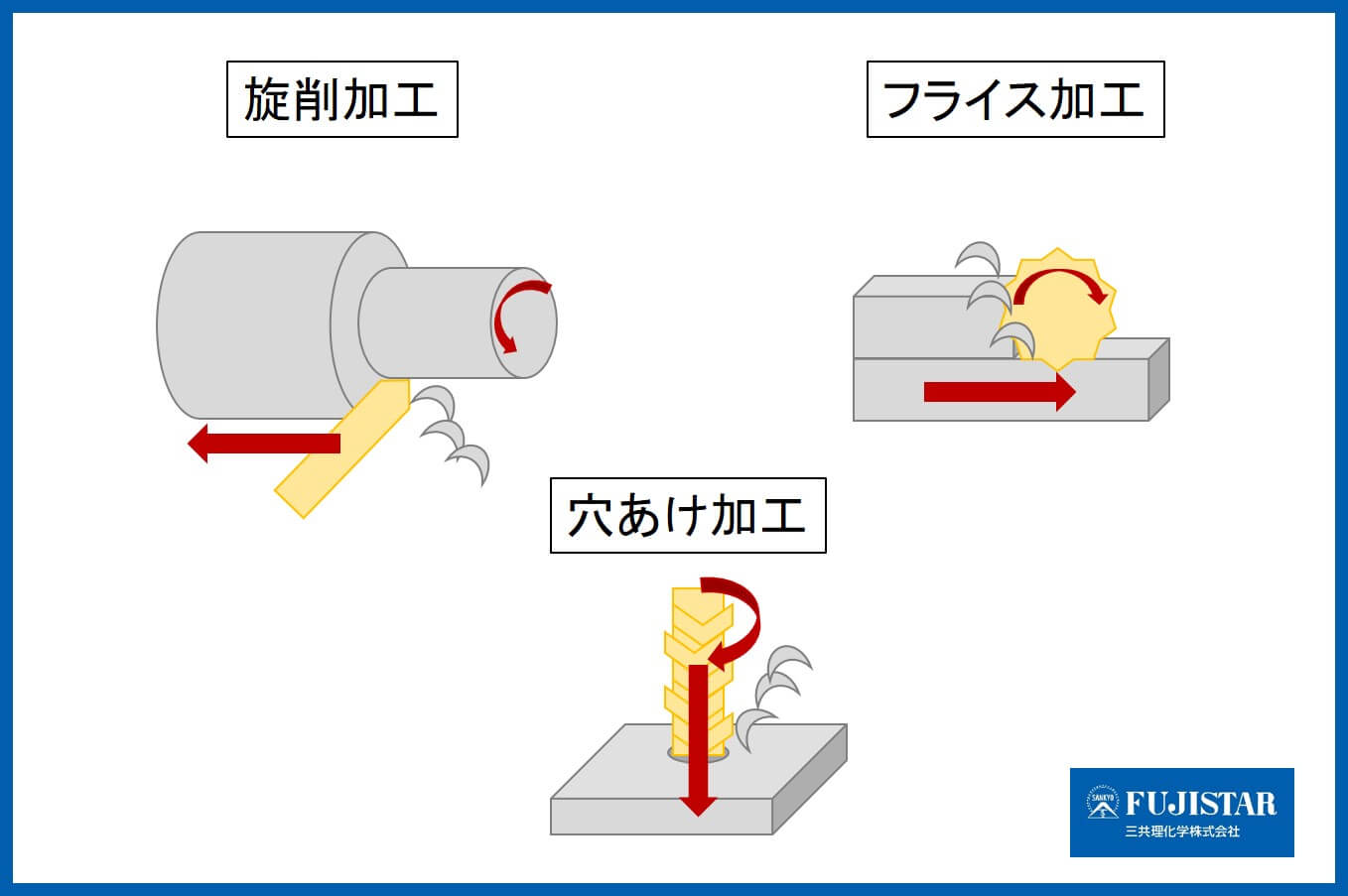

・Turning

This is a machining method in which the object is rotated and a special tool "bite" is applied to the object to shave the outer circumference.

・Milling

This is a machining method in which a special tool "milling cutter" is rotated and applied to a fixed object to cut the material.

・Drilling

This is a processing method in which a special tool called a "drill" is rotated and applied to the object to drill a hole while cutting.

Thus, there are several types of cutting processes, and it is necessary to use different processing methods depending on which part of the object is to be cut.

Characteristics of Grinding Process - How is it different from Grinding and Cutting Processes?

As introduced previouslypolishing, grinding, and cutting are all removal processes (i.e., processes aimed at shaving off unnecessary parts).

First of all, cutting is used in the stage of creating the shape of the product.

It is like cutting out the original raw material in the approximate desired dimensions.

In the subsequent "grinding process," the shape is not significantly changed as in the "cutting process" described earlier.

<Grinding is used to improve dimensional accuracy.

Finally, when added value (improved appearance) or precision is required, polishing is performed as necessary.

Different machining methods are used depending on the target dimensions and required accuracy.

In this issue, we briefly explained what cutting is.

Through all three sessions, it feels like a similar word.<We hope you now understand that there are differences in the purposes, types, and finishes of grinding, polishing, and cutting processes.

Understanding the subtle differences between the words for the same sharpening and polishing will improve your workpiece as well as your polishing skills.

If you are interested in polishing, please contact Sankyo Rikagaku Co.