There are many advantages to satin finishing of metals! How does it work with plating? What is the satin finishing method for stainless steel?

Have you ever heard of a processing method called satin?

As the name suggests, this is a processing method that gives the surface of the metal a rough texture like theskin of a pear.

If you have never heard of satin processing, you will be surprised to learn that this process is used for manymetal products around you, such as doorknobs and cups.

The reason why it is so widespread is related to the fact that satin processing is a very useful method ofworking metals with many advantages.

In this issue, we will explain about the pear finish processing of such metals.

Table of Contents

1. What is the satin Finish on Metal? Pearskin finish on stainless steel that goes well with plating

2. What are the advantages and disadvantages of satin finish on stainless steel? Why do you do a satinfinish on metal?

3. What is the best way to do a pear finish on metal? What is the best method for pear-finishing stainlesssteel?

4. Sankyo Rikagaku's Blasting Equipment Recommended for Pearskin Finish on Metal - Effective for Pearskin Finishon Stainless Steel

5. Pearskin finish gives the metal new possibilities.

1. What is the satin Finish on Metal? Pearskin finish on stainless steel that goes well with plating

satin treatment is a processing method that improves the appearance and functionality of metal surfaces andother materials by creating minute irregularities on their surfaces.

There are various patterns depending on the degree of micro unevenness. Typical examples include glossy satin,semi-glossy satin, and matte satin.

Pearskin finish also works well with plating, which creates a protective coating and prevents corrosion.

Corrosion resistance can also be further improved by combining two types of plating, such as chrome plating andnickel plating.

2. What are the advantages and disadvantages of satin finishing on stainless steel? Why do you do asatin finish on metal?

Pearskin processing offers many advantages, including improved appearance.

<Advantages of Pearskin Finish>

・Improvement of appearance quality

The rough texture enhances the beauty of the material itself, which cannot be achieved by painting, and createsa sense of luxury.

For this reason, the satin process is often incorporated into precious metals and other decorative items.

Also, by controlling the degree of gloss, changes in texture can be enjoyed.

For example, a higher gloss gives the impression of presence, while a less glossy satin finish creates asubdued atmosphere.

・Excellent antifouling effect

Buttons, doorknobs, smartphones, computers, etc., are easily covered with fingerprints and sebum due to theirfrequent contact, making them conspicuously dirty.

Pearskin finish on its surface has the effect of making stain adhesion less noticeable.

Furthermore, the pear-finished surface diffusely reflects light, making scratches as well as stainsinconspicuous.

There is no worry about the paint peeling off over time, as is the case with antifouling coatings.

・Processing is possible with any material

We can process iron, cast metal, copper, stainless steel, and aluminum in a variety of metals.

・Adhesion up

The microscopic surface irregularities increase surface area and improve adhesion for painting and plating.

<Disadvantages of Pearskin Finish>

・Occurrence of gloss

Scratches and friction from years of use may gradually even out the surface finish, causing it to lose itspearlescent finish and become shiny.

・Processing costs money

3. What is the best way to do a pear finish on metal? What is the best method for pear-finishing stainlesssteel?

Pearskin finishing can be roughly classified into mechanical and chemical methods.

・wire brush method :A wire brush is used to physically create an uneven surface on the metal surface.

・Liquid Honing Method:A liquid containing fine abrasive particles is sprayed onto the metalworking surface tocreate an uneven surface.

・Blasting method :Compressed air is used to blow fine particles onto the surface to create an uneven surface.

The blasting method can be used to create a uniform pear finish on parts with complex shapes by anyone, and isthe best method for pear finishing of stainless steel.

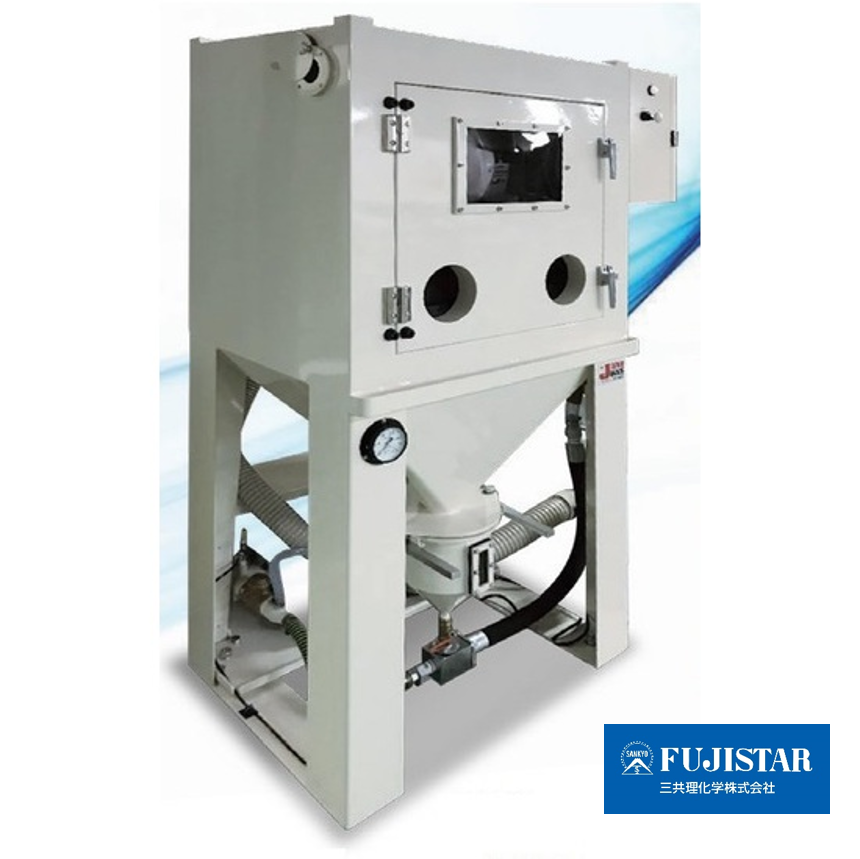

4. Sankyo Rikagaku's Blasting Equipment Recommended for Pearskin Finish on Metal - Effective for PearskinFinish on Stainless Steel

Sankyo Rikagaku's blasting equipment can process even complex shapes of treated surfaces.

The finish can be freely controlled by varying the type of projectile (media), ejection speed, and pressure.

In addition, the system is compatible with automation, so it is not dependent on operators and can bemanufactured to the required quality.

PRODUCT DETAILSCONTACT US

5. The pear finish gives the metal new possibilities.

In this article, we briefly introduced the pear finish process for metals.

The satin finish, which enhances the original beauty of materials that cannot be expressed by paint, is idealfor products that require design, but it can also add new value to products by adding functionality.

Please feel free to contact Sankyo Rikagaku if you are interested in pear-finishing of metals.